🌡️ Revolutionizing Electronics Assembly with Specialized Masking Solutions

The transition to lead-free soldering processes has intensified thermal requirements in electronics manufacturing, creating critical demands for high-temperature masking tapes that can withstand extreme processing conditions while maintaining precision protection.

🎯 Technical Specifications & Performance Metrics

| Parameter | Standard Tapes | Our High-Temp Tapes |

|---|---|---|

| Temperature Resistance | 150-200°C | 260-320°C |

| Solder Wave Survival | Single pass | Multiple exposures |

| Residue-Free Removal | Often fails | Guaranteed clean |

| Dielectric Strength | Medium (2-4kV) | High (5-8kV) |

💡 Key Applications in Lead-Free Processes

- PCB protection during reflow soldering

- Selective conformal coating masking

- Component shielding in wave soldering

- High-temperature potting containment

🚀 Product Solutions

Thermo-Shield® 320 Series – Withstands peak temperatures of 320°C

Clean-Mask® Lead-Free Series – Zero residue after multiple thermal cycles

Precision-Edge® PCB Tapes – Laser-cut for exact component coverage

Contact Our Technical Team: Email | Website | Free Samples

VHB Tape Alternatives for Structural Bonding in Marine Composite Applications

Next-Generation Bonding Solutions for Harsh Marine Environments

🌊 Overcoming Marine Bonding Challenges

Traditional VHB tapes face limitations in marine composite applications where constant moisture, UV exposure, and thermal cycling demand superior performance from structural bonding alternatives.

⚓ Performance Comparison in Marine Conditions

| Property | VHB Tapes | Marine-Grade Alternatives |

|---|---|---|

| Salt Spray Resistance | 500 hours | 2000+ hours |

| UV Stability | 6 months | 5+ years |

| Water Immersion | Moderate degradation | No performance loss |

| Composite Compatibility | Variable | Optimized for marine composites |

🛥️ Marine-Specific Applications

- Deck-to-hull bonding

- Composite panel assembly

- Hardware attachment in wet areas

- Through-hull component mounting

🌟 Recommended Products

Aqua-Bond® Marine Series – Specifically formulated for saltwater environments

Struct-Bond® Composite Adhesives – Engineered for fiberglass and carbon fiber

Seal-Stick® Waterproof Tapes – Combines bonding and sealing in one step

Expert Support Available: Marine Applications Engineering | Technical Data Sheets | Emergency Support

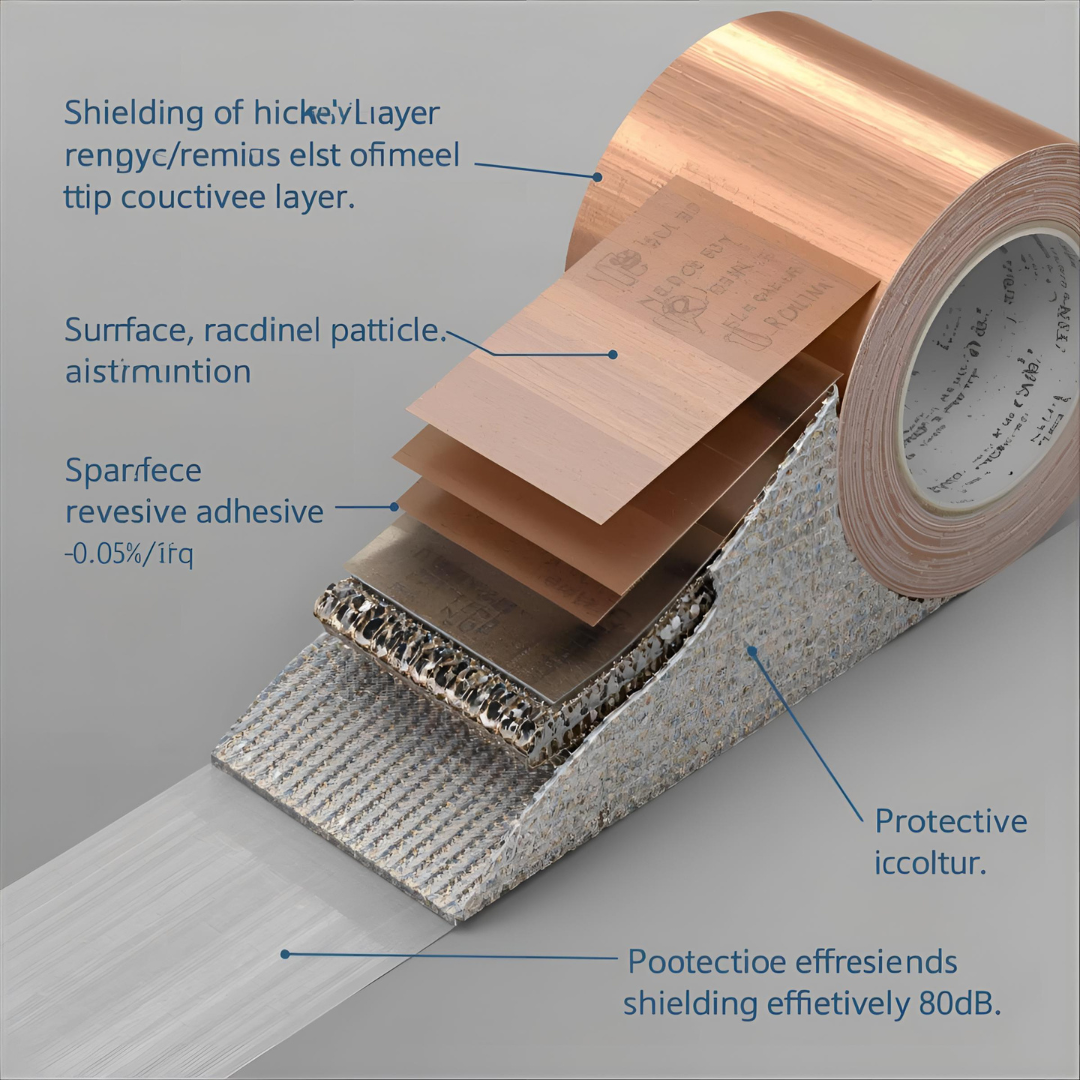

EMI Shielding Tapes with Environmental Sealing Properties for Outdoor Electronics

Dual-Function Protection for Demanding Outdoor Applications

🌐 Integrated EMI Shielding and Environmental Protection

Modern outdoor electronics require comprehensive protection solutions that combine EMI/RFI shielding with robust environmental sealing capabilities to ensure reliability in harsh outdoor conditions.

📊 Shielding & Sealing Performance Data

| Feature | Standard EMI Tapes | Our Advanced Solutions |

|---|---|---|

| Shielding Effectiveness | 40-60 dB | 70-90 dB |

| IP Rating | IP54 | IP68 certified |

| Temperature Range | -20°C to 85°C | -40°C to 125°C |

| UV Resistance | Limited | 5-year warranty |

🏔️ Critical Outdoor Applications

- 5G outdoor infrastructure

- Automotive radar systems

- Industrial IoT sensors

- Renewable energy controls

💫 Product Innovations

Shield-Seal® Dual-Function Tapes – EMI shielding with environmental protection

Weather-Block® Conductive Tapes – Maintains conductivity in wet conditions

Outdoor-Grade EMI Tapes – Specifically for telecommunications equipment

Technical Consultation: EMI Solutions Team | Application Support | Custom Formulations

Thermally Conductive Phase Change Tapes for Power Module Heat Dissipation

Advanced Thermal Management for High-Power Electronics

🔥 Revolutionizing Power Electronics Cooling

As power module densities continue increasing, thermally conductive phase change tapes provide breakthrough thermal management solutions by combining the application convenience of tapes with the performance of thermal interface materials.

❄️ Thermal Performance Comparison

| Characteristic | Standard Thermal Tapes | Phase Change Tapes |

|---|---|---|

| Thermal Conductivity | 1-2 W/mK | 3-5 W/mK |

| Contact Resistance | High | Ultra-low |

| Long-Term Stability | Degrades over time | Maintains performance |

| Application Pressure | High required | Low pressure sufficient |

⚡ Power Electronics Applications

- IGBT and power module attachment

- Automotive power converters

- Renewable energy inverters

- Server power supplies

🌡️ Advanced Product Line

PhaseCool® Thermal Tapes – Industry-leading 5.0 W/mK conductivity

Power-Bond® Phase Change Series – Specifically for power semiconductor mounting

Therma-Change® Interface Tapes – Combines bonding and thermal management

Thermal Engineering Support: Power Electronics Team | Thermal Analysis | Urgent Samples

All products manufactured under ISO 9001:2015 quality standards with full traceability and technical documentation. Global shipping available with local technical support in major industrial regions.

#AdvancedMaterials #EngineeringSolutions #ManufacturingInnovation #TechnicalTapes #IndustrialAdhesives