The Definitive Guide to Heat-Resistant Adhesive Solutions for Extreme Environments

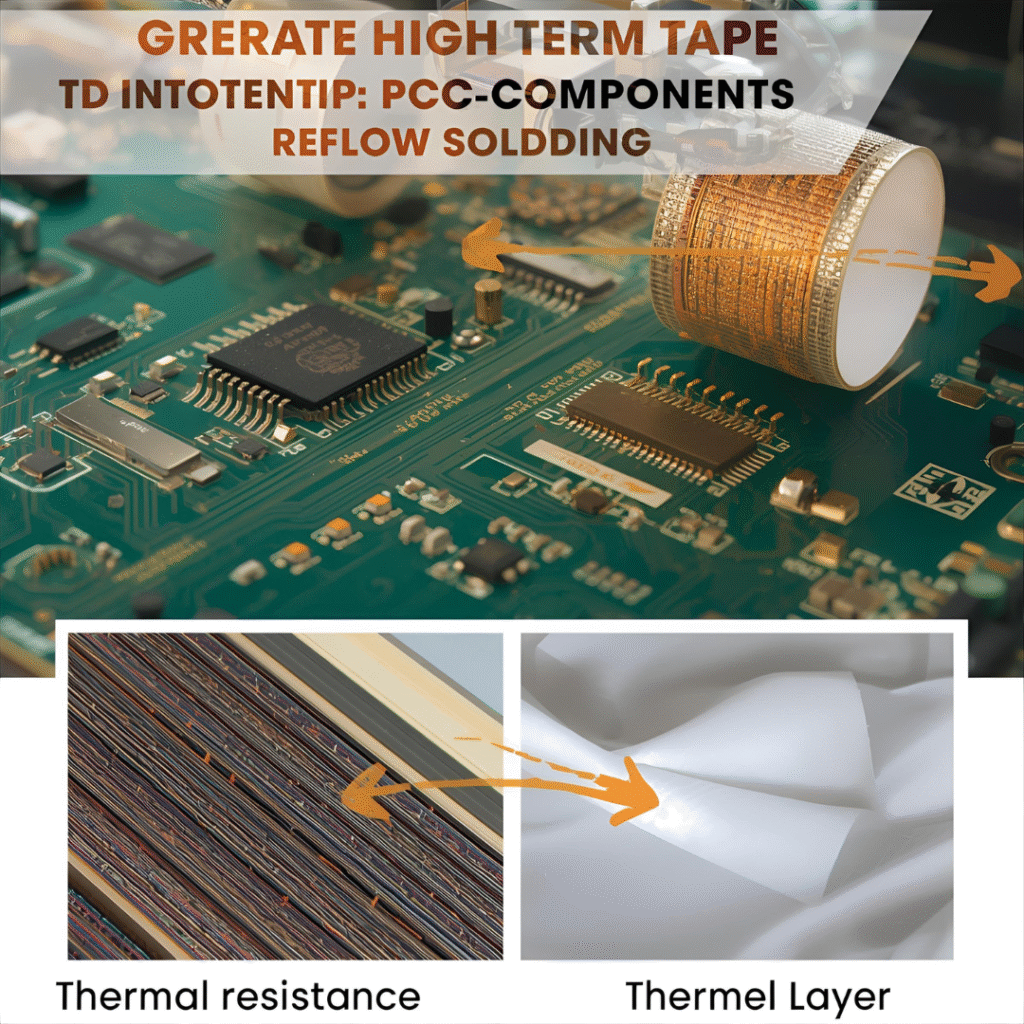

1. What Are High-Temp Tapes?

High-temperature tapes are specialized pressure-sensitive adhesive tapes designed to withstand extreme heat, thermal cycling, and harsh environmental conditions without degrading. They are engineered with heat-resistant backings (e.g., polyimide, glass cloth, aluminum foil) and advanced adhesives (silicone, acrylic) for applications ranging from electronics manufacturing to industrial insulation.

2. Types of High-Temp Tapes

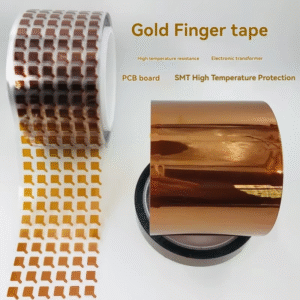

- Polyimide Tapes (e.g., Kapton®)

- Properties: Continuous resistance up to 260°C, excellent dielectric strength, thickness: 0.03–0.15mm.

- Applications: PCB solder masking, circuit protection, coil wrapping.

- Glass Cloth Tapes

- Properties: Tear-resistant, withstands 500°C briefly, mechanical durability.

- Applications: Insulation in motors, transformers, and aerospace components.

- Aluminum Foil Tapes

- Properties: Reflects heat and radiation, operates up to 300°C, moisture-resistant.

- Applications: HVAC duct sealing, automotive exhaust shielding, thermal management.

- Silicone Rubber Tapes

- Properties: Self-fusing, stretchable, resistant to 200°C continuously.

- Applications: Pipe insulation, wire harnessing, gasketing.

3. Key Performance Metrics

| Parameter | Typical Range | Importance |

|---|---|---|

| Temperature Resistance | -70°C to 300°C+ | Determines operational limits |

| Adhesive Peel Strength | 10–40 N/25mm | Ensures bonding under heat |

| Dielectric Strength | 3–7 kV/mm | Critical for electrical insulation |

| Tensile Strength | 50–150 N/cm | Mechanical integrity |

| Thickness | 0.03–0.5 mm | Flexibility and conformability |

4. Industry Applications

- Electronics: Solder masking during reflow, flexible circuit insulation.

- Automotive: Engine bay wire harnessing, exhaust heat shielding.

- Aerospace: Thermal protection for avionics, insulation in propulsion systems.

- Industrial: Sealing in ovens, furnaces, and heavy machinery.

5. Selection Guidelines

- Electronics Manufacturing: Polyimide tapes for solder masks (260°C resistance).

- High-Power Motors: Glass cloth tapes for insulation (500°C peak resistance).

- Thermal Management: Aluminum foil tapes for heat reflection.

- Outdoor/Weather-Exposed Applications: Silicone rubber tapes for UV/ozone resistance.

6. Future Trends & Challenges

- Trends: Nanocomposite adhesives for higher thermal conductivity, eco-friendly silicone alternatives, thinner tapes with higher strength.

- Challenges: Adhesive stability above 400°C, balancing flexibility with heat resistance.

7. Why Choose Professional High-Temp Tapes?

Technical support for adhesion testing and thermal cycling validation.

Custom widths and lengths for specific applications.

Compliance with UL, ROHS, and aerospace standards (e.g., MIL-STD).

Products by Category

-

Black Amber Polyimide Film – High Temp Electrical Insulation

-

Direct Factory Sale Self-Adhesive Polyimide High Temperature Die-Cut Tape

-

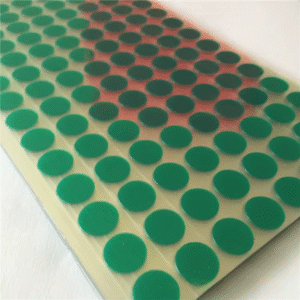

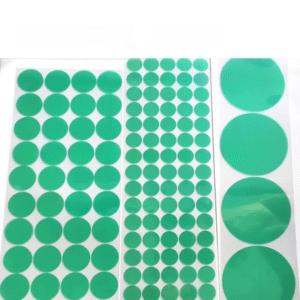

ECO-FRIENDLY HIGH-TEMP MASKING TAPE – Green PET/Silicone for Precision Die-Cutting

-

ECO-FRIENDLY PCB MASKING TAPE – Green High-Temp PET Film for Plating Protection

-

High Temperature Insulation Masking PI Film PCB Polyimide Tape

-

High Temperature PI Polyimide Tape