The RFQ Secret: Why Complete Information Gets You Better Parts & Prices 💡

A well-prepared Request for Quotation (RFQ) is more than just paperwork—it’s the foundation for successful part production and cost-effective pricing. Many projects face delays and budget overruns simply because of incomplete RFQ information. Let’s transform how you prepare die-cutting quotations.

📋 The Essential RFQ Checklist: 8 Critical Components

1. 📐 PART DESIGN FILES

- 2D DXF/DWG Files (industry standard)

- 3D STEP/IGES Files (for complex parts)

- PDF with Dimensions (as backup)

- Application Drawings (show how part is used)

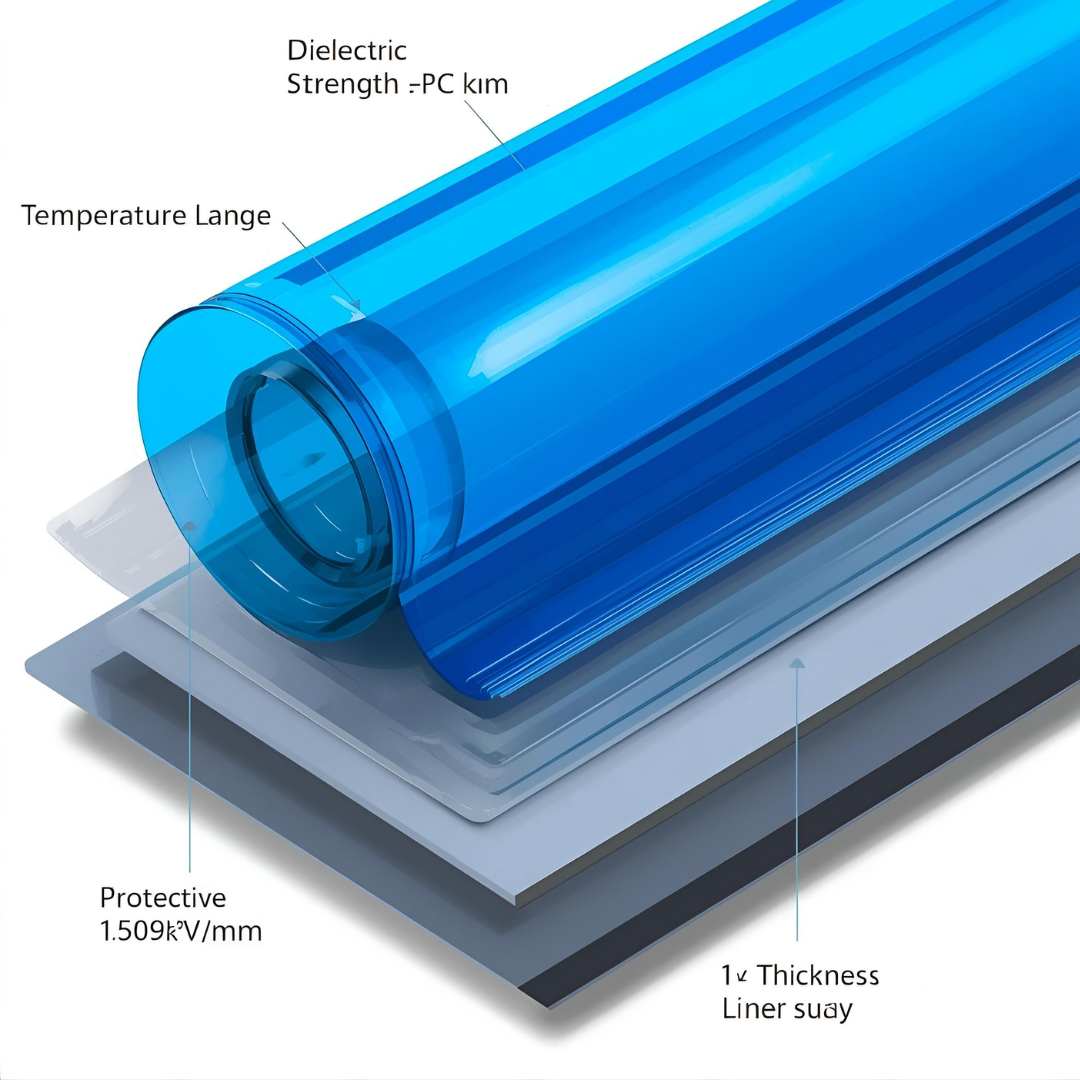

2. 🧱 MATERIAL SPECIFICATIONS

- Material Type (PET, PI, Foam, Non-woven)

- Thickness (with tolerance range)

- Color & Finish requirements

- Adhesive Type & Liner specifications

- UL/CSA/RoHS Certifications needed

3. 📊 QUANTITY & SCHEDULE

- Prototype Quantity (if needed)

- Initial Production Run

- Annual Forecast Volume

- Required Delivery Date

4. 🎯 CRITICAL-TO-QUALITY (CTQ) FACTORS

- Key Dimensions with tolerances

- Visual Standards (acceptable flaws)

- Performance Requirements

- Testing & Validation needs

⚡ Pro Tips for RFQ Excellence

DESIGN FOR MANUFACTURABILITY:

- Specify non-critical dimensions separately

- Indicate burr direction requirements

- Note grain direction preferences

- Identify cosmetic surfaces

COST-SAVING STRATEGIES:

- Ask about standard material alternatives

- Inquire about stock tooling availability

- Consider panelization for small parts

- Explore alternative conversion methods

🚀 Advanced RFQ Elements for Complex Projects

MULTI-MATERIAL ASSEMBLIES:

- Provide layer stack-up diagrams

- Specify lamination requirements

- Detail orientation relationships

- Define bond strength expectations

QUALITY & COMPLIANCE:

- ISO 9001/13485 requirements

- First Article Inspection needs

- Statistical Process Control requirements

- Material Certification demands

- Traceability level required

📝 The Manufacturer’s Wishlist: What We REALLY Need to Quote Accurately

THE GOOD RFQ:

- Complete drawings with revisions

- Material specifications or samples

- Clear quantity breakdown

- Realistic timeline

- Quality expectations

THE GREAT RFQ ADDS:

- Application photos/diagrams

- Competitor samples for reference

- Budget range guidance

- Willingness to discuss alternatives

- Long-term partnership interest

🎯 Your RFQ Success Formula

BEFORE YOU SEND:

✅ All critical dimensions specified

✅ Material alternatives considered

✅ Realistic quantities provided

✅ Quality standards defined

✅ Timeline communicated

Download our complete RFQ checklist to ensure nothing gets missed in your next project submission.

💡 Why Partnering Streamlines Everything

The most successful die-cutting projects come from manufacturing partnerships, not just transactional RFQs. When suppliers understand your:

- End-use application

- Performance requirements

- Growth plans

- Quality standards

…they can provide value engineering suggestions and cost-saving alternatives that simple RFQ responses might miss.

🌟 Ready to Transform Your RFQ Process?

Stop wasting time on back-and-forth emails and incomplete quotations. Our streamlined RFQ system ensures you get:

- Faster Quotes (24-48 hour typical response)

- More Accurate Pricing (complete information = better quotes)

- Engineering Support (free DFM analysis)

- Material Guidance (expert recommendations)

➡️ Download Your FREE RFQ Checklist & Template!

Get our professionally designed:

- Complete RFQ checklist

- Editable RFQ template

- Drawing preparation guide

- Tolerance specification sheet

Submit your next RFQ with confidence and receive comprehensive, competitive pricing with actionable engineering feedback.

Contact us today for your free RFQ toolkit and discover the difference complete information makes!

Keywords Integrated: die-cut RFQ, custom die-cutting quotes, request for quotation, die-cut part specifications, material specifications, prototype quantity, manufacturing partnerships, value engineering, DFM analysis, tolerance specification, quality standards, material alternatives, cost-saving alternatives, engineering support, RFQ checklist, accurate pricing, die-cutting quotations.