Selecting the ideal double-sided tape can feel like a complex puzzle. Using the wrong adhesive leads to product failure, costly rework, and reputational damage. This definitive guide cuts through the confusion, providing a clear, step-by-step framework for engineers, designers, and procurement specialists to master industrial adhesive selection.

Forget generic solutions. Precision die-cutting transforms standard tape rolls into high-performance components. At DieCutChina, we don’t just sell tape; we deliver custom die-cut adhesive solutions that guarantee reliability in your assembly process.

🚀 Step 1: Deconstruct Your Substrate Materials

The foundation of a strong bond is material compatibility.

- Plastic to Plastic Bonding: Beware of low-surface-energy (LSE) plastics like Polypropylene (PP) and Polyethylene (PE). They require specialized acrylic foam tapes or VHB tapes designed to wet-out these challenging surfaces.

- Metal Bonding Solutions: For bonding metal to metal or metal to plastic, high-strength, weather-resistant options like our heavy-duty mounting tapes are essential to resist vibration and thermal expansion.

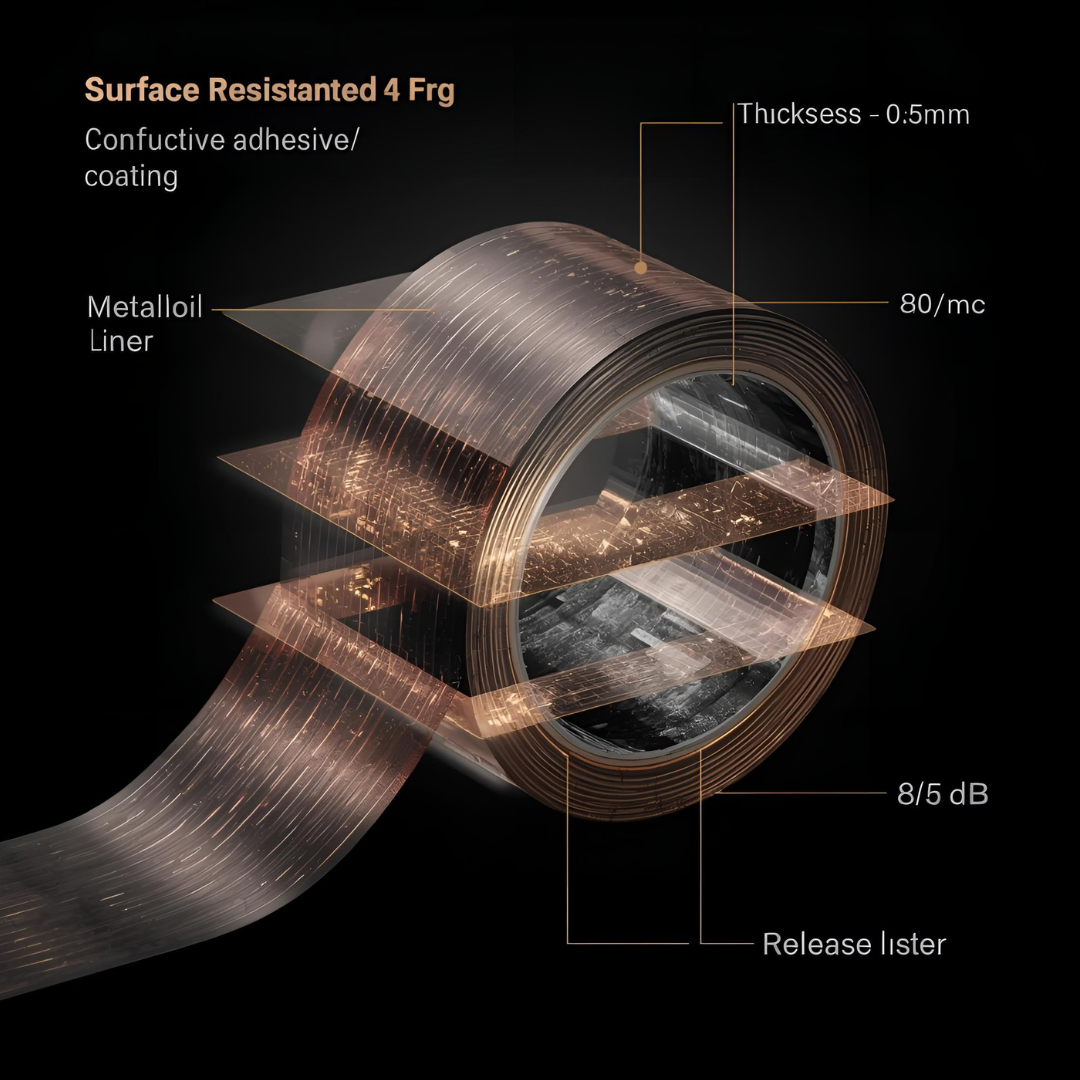

- Electronic Component Attachment: Securing EMI shielding cans or FPCs (Flexible Printed Circuits) demands conductive adhesives or low-outgassing, ultra-thin acrylic tapes to prevent interference and short-circuiting.

🔥 Step 2: Analyze the Application Environment

An adhesive that performs in a lab may fail in the field. Critical environmental factors include:

- Temperature Resistance: Standard acrylic tapes handle -20°C to 120°C. For high-temperature applications near engines or motors, silicone-based adhesives or specialty acrylics are necessary.

- Chemical & UV Exposure: Outdoor applications or exposure to solvents require tapes with robust weatherability and resistance to degradation.

- Impact & Shear Stress: Dynamic loads and sustained weight demand the viscoelastic properties of closed-cell foam tapes, which absorb energy and resist creep.

💡 Step 3: Define Your Performance & Process Needs

Finally, consider your production line and final product requirements.

- Thickness & Conformability: Filling gaps or bonding uneven surfaces? A compressible foam tape is the perfect gap filler.

- Dieline & Precision: Complex shapes require expert custom die-cutting services. We convert your material into ready-to-apply parts with ±0.15mm tolerances.

- Quick-Stick & Final Bond: Understand the difference between initial tack (quick-stick) and ultimate bond strength, which develops over 24-72 hours.

✅ Your Next Step: From Concept to Reliable Assembly

Navigating the world of 3M VHB alternatives, PET double-sided film, and non-conductive thermal tapes is our expertise. Let us be your custom die-cut manufacturer in China.

Explore Our Adhesive Solutions:

- Browse our extensive die-cut adhesive products here: [Link to Product Category Page – e.g., https://diecutchina.com/offerings/]

Ready for a Perfect Bond?

Stop guessing and start building with confidence. Submit your requirements and 2D/3D drawing for a expert review and competitive quotation.

📧 Contact Us for a Free Engineering Assessment & Quote Today!

[Link to Contact Page – e.g., https://diecutchina.com/contact/]

Keywords Integrated: double-sided tape, adhesive selection, custom die-cut adhesive, plastic bonding, metal bonding, electronic component attachment, VHB tape, acrylic foam tape, conductive adhesive, high-temperature tape, custom die-cutting services, die-cut manufacturer China, industrial adhesive selection, EMI shielding, FPC attachment, foam tape, precision die-cutting.