Electromagnetic Interference (EMI) and Radio-Frequency Interference (RFI) are among the most common and frustrating challenges faced by electronics designers today. Uncontrolled, they can cause data corruption, performance degradation, and outright device failure. Ensuring electromagnetic compatibility (EMC) is not optional—it’s a requirement.

One of the most effective solutions is the use of EMI shielding gaskets. These components form a conductive seal between two surfaces, creating a Faraday cage that contains electromagnetic emissions and protects sensitive components from external interference.

This guide will walk you through the types of gaskets available and how to choose the right one for your application.

Understanding How EMI Shielding Gaskets Work

At their core, EMI gaskets work by providing a continuous, low-impedance electrical path between a metal housing and its cover, or between different segments of an enclosure. This path effectively “grounds” out electromagnetic waves, preventing them from escaping or entering. The effectiveness of this shield is measured in decibels (dB) and referred to as Shielding Effectiveness (SE).

The key to success lies not just in the gasket itself, but in achieving uniform compression and solid metal-to-metal contact on both sides of the gasket.

Types of EMI Shielding Gaskets and Their Applications

Selecting the right gasket material is critical. Each offers a unique balance of shielding performance, environmental sealing, compression force, and cost.

1. Conductive Elastomers (e.g., Conductive Silicone)

These gaskets combine silicone rubber (which provides excellent environmental sealing against moisture, dust, and other contaminants) with conductive particles like silver, nickel, or carbon.

- Best for: Harsh environments where both high levels of EMI shielding and an IP-rated environmental seal are required. Common in aerospace, military, and outdoor industrial equipment.

- Explore our range of high-performance <a href=”https://diecutchina.com/shop/conductive-silicone/” title=”Conductive Silicone Gaskets” target=”_blank”>conductive silicone gaskets</a> for your most demanding applications.

2. Fabric-over-Foam (FoF)

FoF consists of a conductive fabric (often nickel/copper or silver-coated) wrapped over a resilient polyurethane foam core. It offers excellent compression set recovery and low closure force.

- Best for: Applications with large gaps or uneven surfaces, and where low compression force is needed to avoid warping delicate housings. Ideal for consumer electronics, data storage, and telecommunications hardware.

- Our precision-die-cut <a href=”https://diecutchina.com/shop/fabric-over-foam/” title=”Fabric over Foam Gaskets” target=”_blank”>fabric over foam gaskets</a> provide exceptional shielding and surface conformity for sleek device designs.

3. Conductive Polyurethane Foams

These are lightweight, compliant open-cell polyurethane foams that are plated with conductive metals. They are a cost-effective solution for many applications.

- Best for: Shielding cabinet doors, access panels, and enclosures where weight and cost are significant factors. Offers good shielding in a compressible form factor.

- Find an economical shielding solution with our reliable <a href=”https://diecutchina.com/shop/conductive-foam/” title=”Conductive Foam” target=”_blank”>conductive foam products</a>.

4. Metal Strips (Beryllium Copper, Stainless Steel)

Often referred to as “finger stock,” these gaskets are made from thin, resilient metal strips that act as thousands of tiny fingers. They provide the highest possible shielding effectiveness.

For unmatched durability and supreme shielding performance, consider our metal finger stock gaskets

Best for: High-frequency applications and environments requiring extreme durability, high temperatures, and the absolute maximum SE value. Commonly used on doors and panels that are frequently opened and closed.

4 Key Factors for Choosing the Right Gasket

- Shielding Effectiveness (SE): Determine the level of attenuation (in dB) you need across the required frequency spectrum.

- Compression Force: How much force is required to compress the gasket to its optimal height? This must be balanced against the structural integrity of your enclosure.

- Environmental Sealing: Beyond EMI, do you need to protect against moisture, dust, chemicals, or extreme temperatures? Conductive elastomers are the prime choice here.

- Compression Set: This measures the material’s ability to spring back after prolonged compression. A low compression set is vital for long-term performance in devices that are not constantly disassembled.

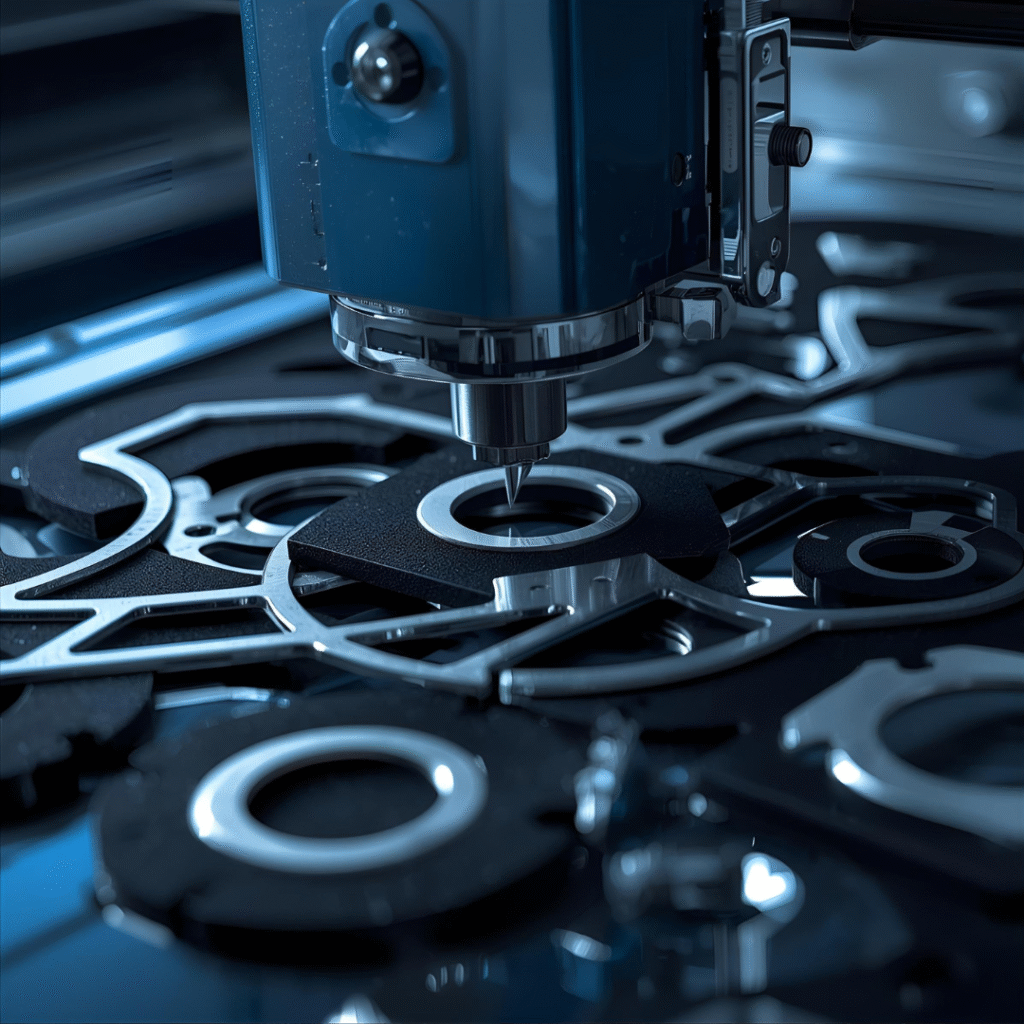

The Critical Role of Precision Die-Cutting

No matter how advanced the material, a poorly manufactured gasket will fail. Precision die-cutting ensures:

- Clean, Burr-Free Edges: Prevents particle shedding that can short-circuit internal components.

- Tight Tolerances: Guarantees a perfect fit every time, ensuring consistent compression and shielding.

- Custom Shapes: Allows for complex geometries tailored to your specific design, maximizing efficiency and performance.

At DieCutChina, we specialize in transforming these advanced materials into perfect, ready-to-install shielding solutions.Contact us today to discuss your project requirements and get a prototype started.

Conclusion

Selecting the right EMI gasket is a multifaceted decision that directly impacts the functionality, compliance, and reliability of your electronic product. By understanding the materials available and the key selection criteria, you can make an informed choice that safeguards your design.

Remember, the best results come from collaborating with your gasket supplier early in the design process to ensure the enclosure, materials, and manufacturing process are all aligned for success.

Ready to Spec Your Shielding Solution? <a href=”https://diecutchina.com/quote/” title=”Request a Quote” target=”_blank”>Request a free quote</a> today and let our experts guide you to the optimal solution for your project.