The Science of Stick: Understanding Modern PSAs 🧠✨

Pressure-sensitive adhesives (PSAs) represent one of the most versatile bonding technologies available to engineers today. Unlike traditional adhesives that require curing, mixing, or heat activation, PSAs deliver instant tack and permanent bonding capability through simple pressure application.

📊 PSA Chemistry 101: The Three Main Families

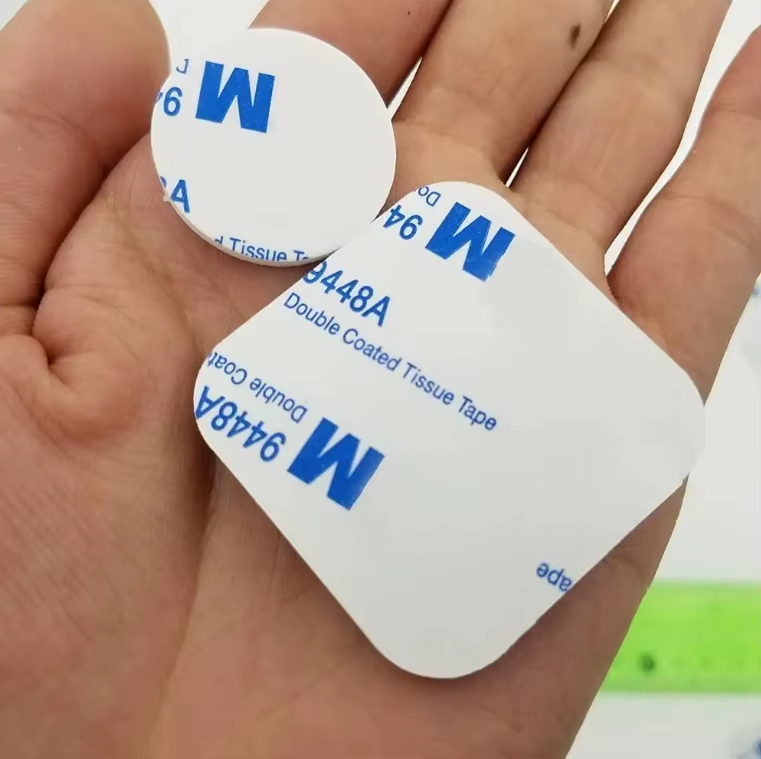

1. ACRYLIC-BASED PSAs: The Performance Champions

- Temperature Range: -40°C to 150°C continuous

- UV Resistance: Excellent for outdoor applications

- Aging Characteristics: Superior long-term stability

- Shear Strength: Outstanding load-bearing capability

- Best For: Automotive, aerospace, and electronic applications

2. RUBBER-BASED PSAs: The Flexible Workhorses

- Initial Tack: Excellent immediate bonding strength

- Flexibility: Conforms well to irregular surfaces

- Cost-Effectiveness: Budget-friendly for many applications

- Limitations: Poor UV and solvent resistance

- Best For: Indoor applications, packaging, temporary bonding

3. SILICONE-BASED PSAs: The Extreme Environment Specialists

- Temperature Tolerance: -60°C to 260°C performance range

- Chemical Resistance: Excellent against solvents and oils

- Electrical Properties: Stable dielectric characteristics

- Cost Consideration: Premium pricing for premium performance

- Best For: High-temperature applications, electronic insulation

⚡ Critical Performance Metrics Every Engineer Should Know

PEEL ADHESION:

Measures resistance to removal force

- Standard Range: 1-20 N/cm

- High Performance: 20-50 N/cm

- Critical for: Structural bonding applications

SHEAR STRENGTH:

Indicates resistance to sliding forces

- Standard: Minutes to hours at room temperature

- High Performance: 100+ hours at elevated temperatures

- Critical for: Load-bearing applications

TACK LEVEL:

Quantifies instant adhesion capability

- Low Tack: Easy repositioning

- High Tack: Immediate permanent bonding

- Critical for: Automated assembly processes

🎯 Advanced PSA Technologies Breaking New Ground

DUAL-CURE SYSTEMS:

Combining pressure sensitivity with secondary curing mechanisms for ultimate performance

ELECTRICALLY CONDUCTIVE PSAs:

Providing both bonding and electrical pathways in electronic assemblies

THERMALLY CONDUCTIVE PSAs:

Managing heat transfer while maintaining secure bonding

REWORKABLE SYSTEMS:

Allowing controlled disassembly for repair and recycling

🚀 Application Mastery: Ensuring PSA Success

SURFACE PREPARATION PROTOCOLS:

- LSE Plastics: Require surface treatment or specialty PSAs

- Metals: Need proper cleaning and degreasing

- Glass & Ceramics: Benefit from primer applications

BONDING OPTIMIZATION TECHNIQUES:

- Pressure Application: 15-50 PSI typically required

- Dwell Time: 24-72 hours for full bond development

- Environmental Factors: Temperature and humidity control

💡 Common Engineering Mistakes & Solutions

PROBLEM: Adhesive failure on low-surface-energy plastics

SOLUTION: Specify LSE-compatible acrylic or silicone PSAs

PROBLEM: Oozing or bleeding in precision applications

SOLUTION: Use precision die-cutting with proper tolerances

PROBLEM: Thermal degradation in high-temperature environments

SOLUTION: Upgrade to silicone-based or high-temperature acrylic PSAs

🌟 The Future of PSA Technology

Emerging innovations include:

- Smart PSAs with sensing capabilities

- Bio-based adhesives for sustainability

- Nano-enhanced formulations for extreme performance

- Digital application systems for precision dispensing

Explore our comprehensive PSA solutions and technical resources through our advanced materials portfolio.

🚀 Ready to Optimize Your Adhesive Applications?

Mastering PSA selection and application can transform your product performance, manufacturing efficiency, and reliability. Our technical team provides:

➡️ FREE PSA Selection Guidance & Sample Testing!

- Material recommendation based on your specific requirements

- Technical data sheets and performance comparisons

- Application engineering support

- Custom formulation options

Stop compromising on adhesive performance. Leverage deep technical expertise and cutting-edge PSA technology for your most challenging applications.

Contact our adhesive specialists today for engineering-grade solutions!

Keywords Integrated: pressure-sensitive adhesive types, PSA performance characteristics, acrylic-based PSAs, rubber-based PSAs, silicone-based PSAs, peel adhesion testing, shear strength measurement, LSE-compatible adhesives, precision die-cutting, high-temperature PSAs, electrically conductive adhesives, thermally conductive PSAs, adhesive application methods, surface preparation, bonding optimization, engineering adhesives.