Thermal Performance Mastery: Tapes That Defy Temperature Extremes ❄️🔥

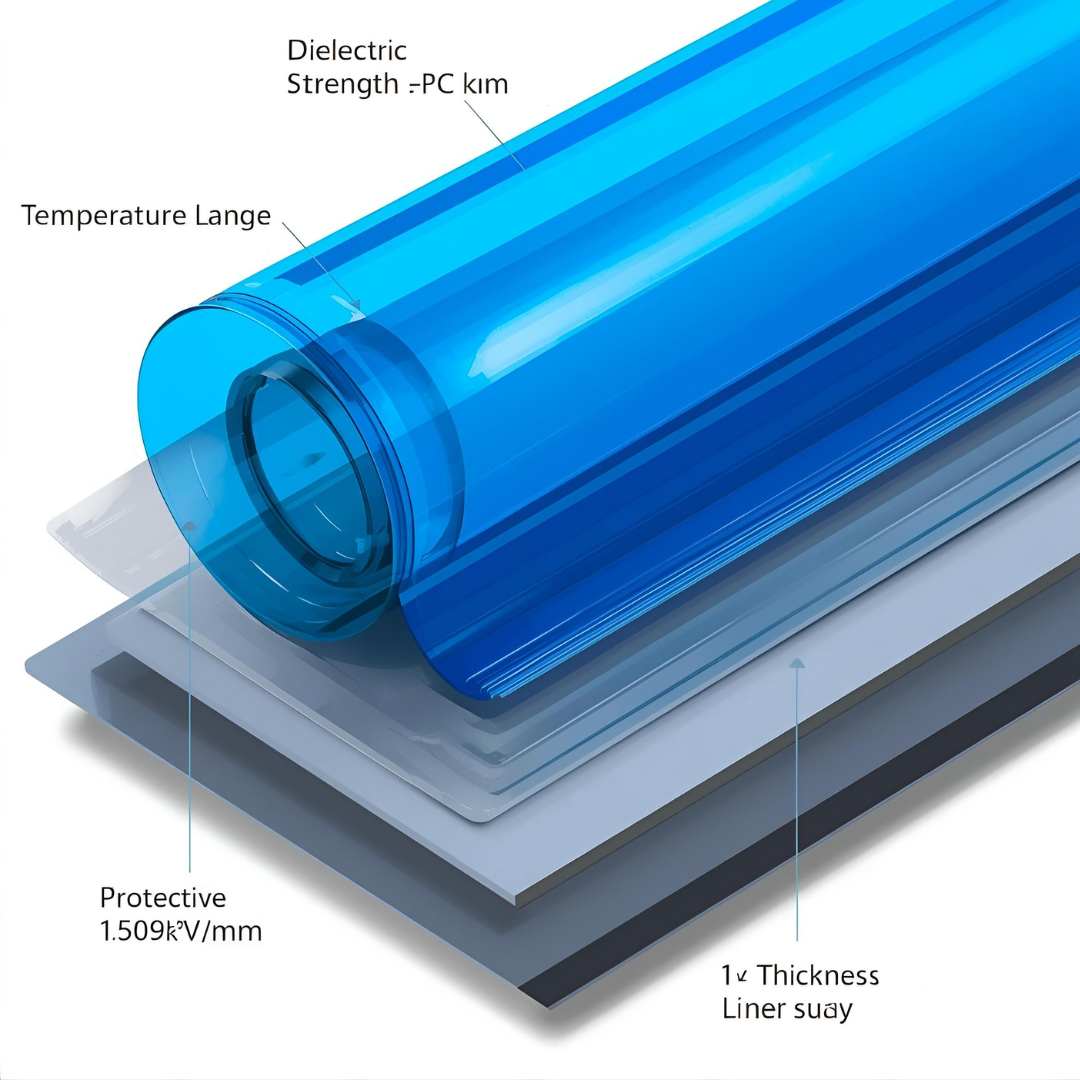

Temperature-resistant double-sided tapes must maintain performance across extreme thermal conditions, from cryogenic applications to high-temperature industrial processes.

📊 Temperature Performance Matrix

| Temperature Range | Tape Type | Key Applications | Performance Characteristics |

|---|---|---|---|

| -60°C to 150°C | Acrylic Foam | Automotive, Electronics | Excellent all-round performance |

| -40°C to 200°C | Silicone | Aerospace, Industrial | High temperature flexibility |

| -269°C to 400°C | Polyimide | Electronics, Space | Extreme temperature stability |

⚡ Advanced Thermal Solutions

HIGH-TEMPERATURE FORMULATIONS:

- Silicone adhesives for continuous high heat

- Polyimide backings for dimensional stability

- Ceramic-filled systems for extreme conditions

- Cross-linked acrylics for improved performance

LOW-TEMPERATURE PERFORMANCE:

- Flexible backings preventing brittleness

- Special plasticizers maintaining tack

- Low Tg adhesives for cold environments

- Arctic-grade formulations for polar applications

🚀 Your Thermal Challenge Solution

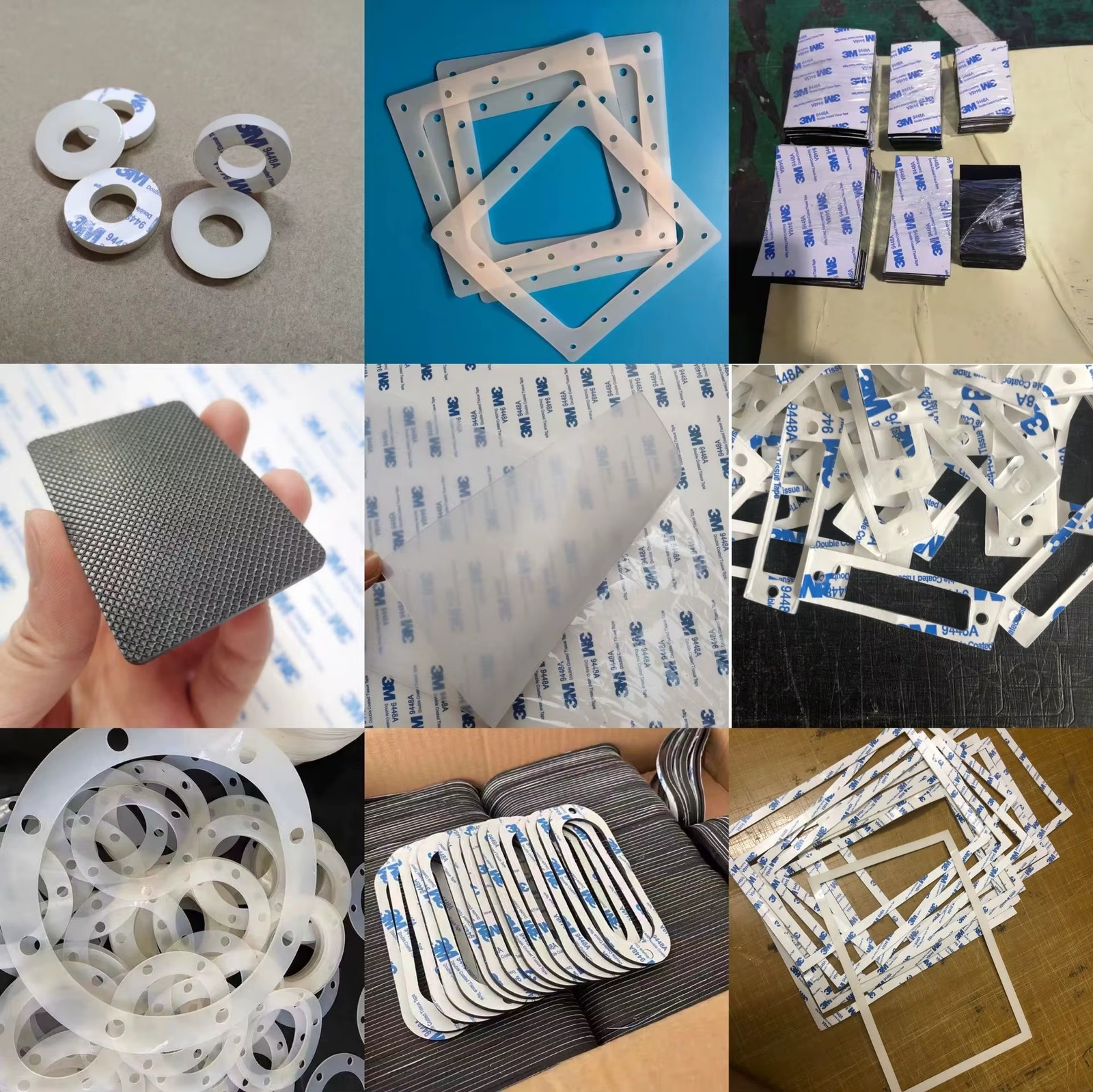

Master extreme temperature applications with our specialized solutions:

➡️ FREE Temperature Application Analysis!

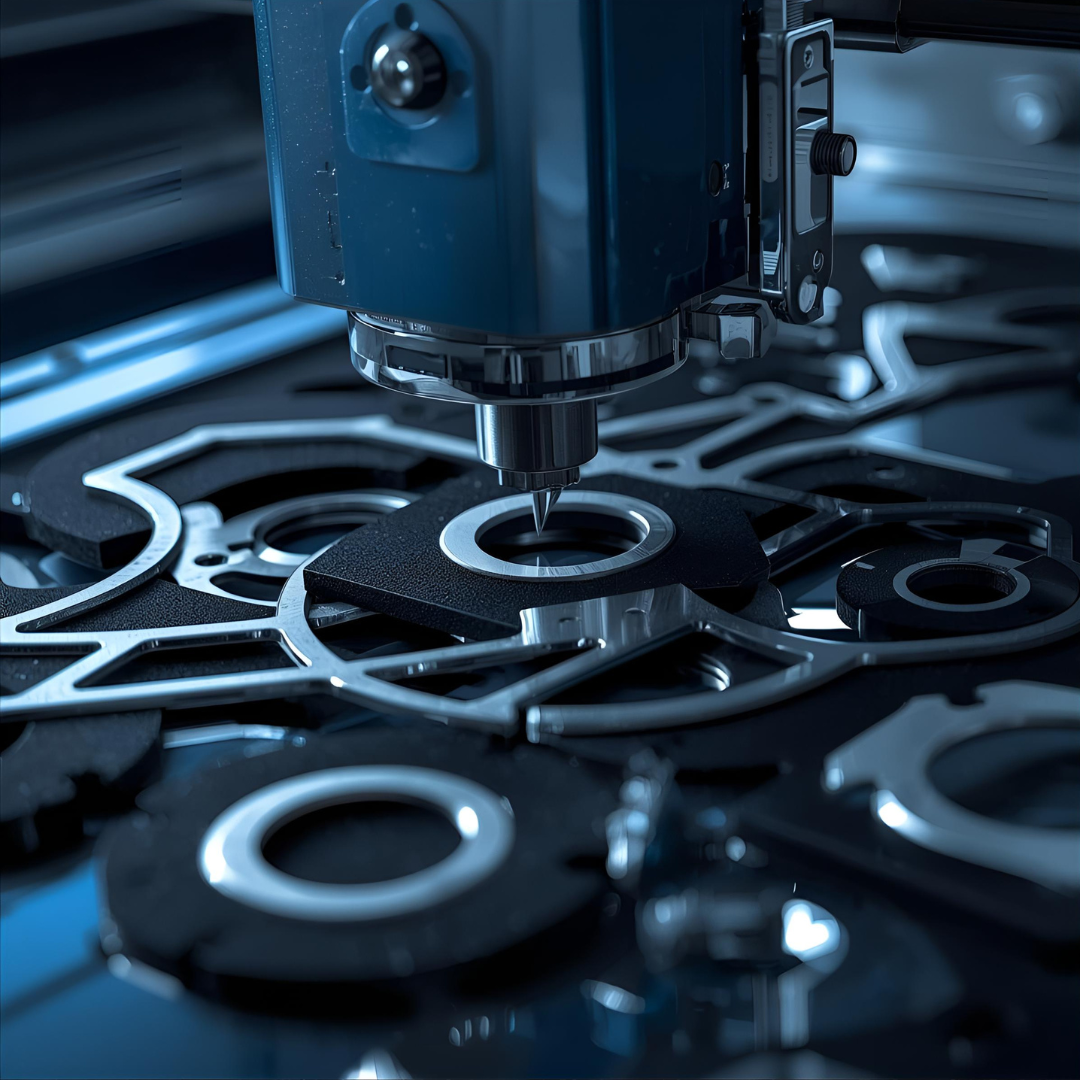

- Thermal cycle simulation testing

- Material selection for specific ranges

- Performance validation under conditions

- Application methodology optimization

Ensure reliable bonding performance across the entire temperature spectrum with engineered tape solutions for extreme conditions.

Contact our thermal specialists today!

Keywords Integrated: double-sided tape temperature resistance, extreme conditions, high-temperature tape solutions, thermal performance, silicone adhesives, polyimide backings, low-temperature performance, thermal cycle testing, arctic-grade formulations.