Defying Thermal Limits: Advanced Tapes for Extreme Environments 🌡️

In harsh industrial environments where temperatures soar, conventional adhesives fail catastrophically. High-temperature resistant tapes emerge as engineered solutions that maintain performance when ordinary materials degrade, ensuring reliability in the most demanding applications.

⚡ Thermal Performance Spectrum: Matching Tapes to Temperature Ranges

MODERATE HEAT ZONE (150°C – 200°C):

- Enhanced acrylic tapes with improved thermal stability

- Rubber-based formulations with thermal stabilizers

- Polyester film backings with silicone adhesives

- PCB masking applications during soldering processes

HIGH-TEMP RANGE (200°C – 260°C):

- Polyimide film tapes with silicone adhesive systems

- Fiberglass cloth composites with high-temp coatings

- Kapton-based solutions for continuous exposure

- Wave solder masking and thermal spray protection

EXTREME ENVIRONMENTS (260°C+):

- Ceramic-filled adhesive systems

- Silicone-free formulations preventing contamination

- Metal foil composites with specialty coatings

- Aerospace and automotive engine applications

🛡️ Application-Specific Thermal Warriors

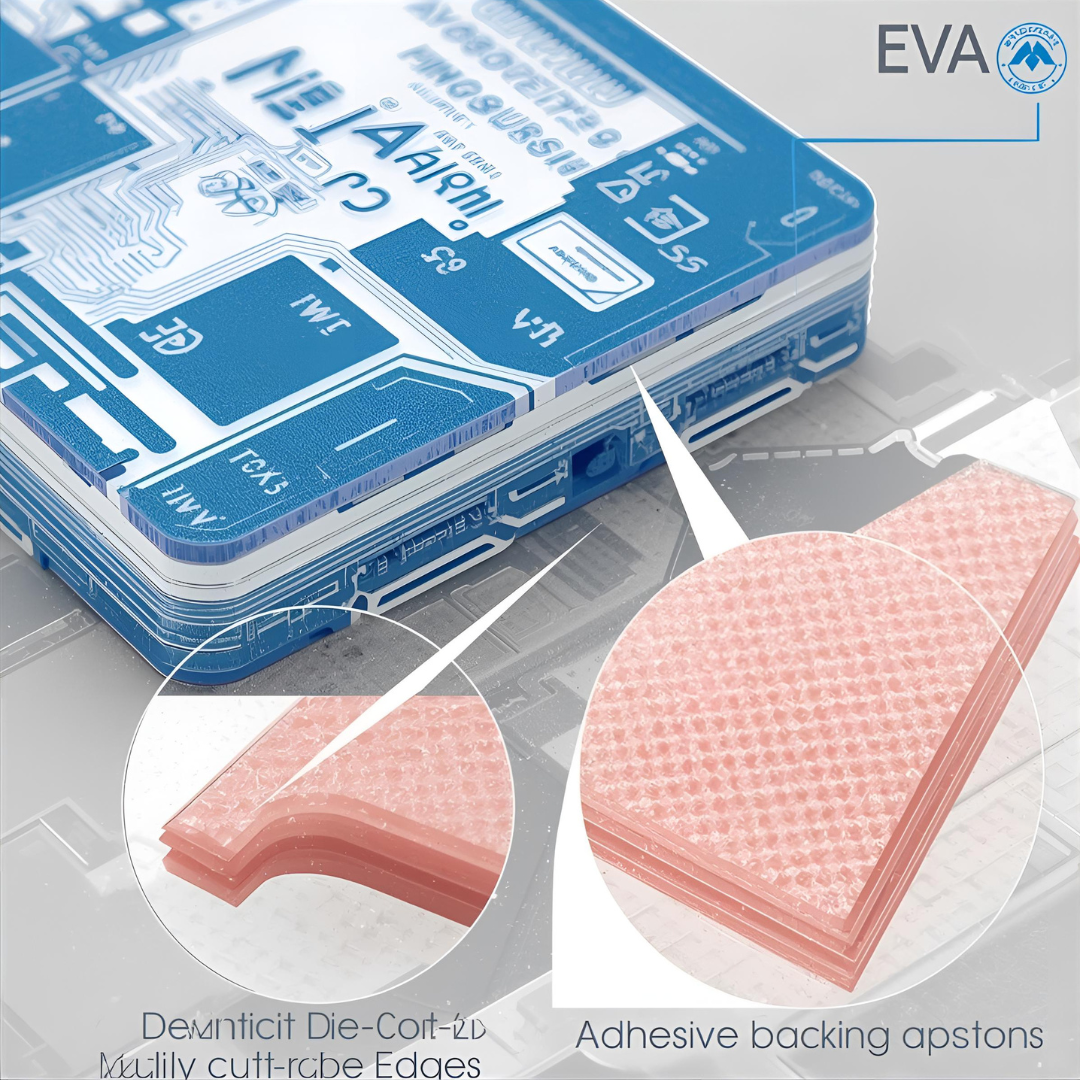

ELECTRONICS MANUFACTURING:

- SMT process protection during reflow soldering

- PCB stiffener attachment in high-temperature environments

- Component masking during conformal coating

- Thermal management in power electronics

AUTOMOTIVE SYSTEMS:

- Engine compartment wiring harness protection

- Exhaust system component attachment

- Brake system insulation and protection

- Under-hood labeling and identification

INDUSTRIAL PROCESSING:

- Powder coating masking for selective protection

- Plasma spray masking in component manufacturing

- Heat treatment protection of critical surfaces

- Industrial oven conveyor system repairs

🔬 Advanced Material Technologies

THERMAL STABILITY INNOVATIONS:

- Cross-linked polymer systems preventing degradation

- Inorganic fillers enhancing thermal conductivity

- Ceramic microspheres providing thermal insulation

- Nano-reinforced adhesives maintaining strength at temperature

PERFORMANCE CERTIFICATIONS:

- UL 746C for long-term thermal aging

- ISO 9001 for quality management

- RoHS compliance for environmental safety

- Specific industry standards (automotive, aerospace)

🚀 Conquer Your Thermal Challenges

Don’t let temperature limitations compromise your manufacturing processes. Our thermal specialists provide:

➡️ FREE High-Temperature Solution Assessment!

- Temperature profiling of your application

- Material recommendations for specific thermal ranges

- Performance testing under simulated conditions

- Custom formulation development

Master extreme thermal environments with engineered tape solutions that deliver reliable performance when ordinary materials fail.

Contact our high-temperature experts today for thermal-defying solutions!

Keywords Integrated: high-temperature industrial tapes, extreme manufacturing conditions, heat-resistant adhesive solutions, polyimide film tapes, Kapton-based solutions, SMT process protection, automotive engine applications, thermal stability innovations, UL 746C certification, custom formulation development.