The Ultimate Guide to EMI Shielding, ESD Protection, and Material Innovation

1. Material Composition and Structure

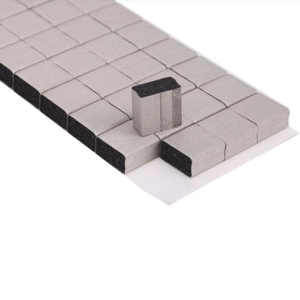

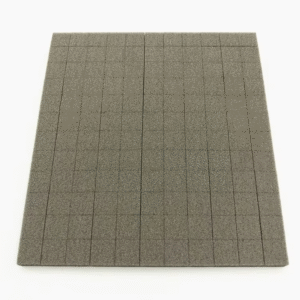

Conductive foam is a composite material typically consisting of:

- Base Material: Polyurethane or polyethylene foam with open-cell or closed-cell structure

- Conductive Layer: Electroless plating of copper/nickel (0.05-0.2μm thickness) or carbon loading

- Surface Resistance: Ranges from 0.01-10 Ω/sq depending on plating density and material thickness

Key Physical Properties:

- Density: 0.03-0.25 g/cm³ (customizable based on application)

- Compression Deflection: 5-50 kPa (at 25% compression)

- Operating Temperature: -40°C to 85°C (standard), up to 125°C (high-temp versions)

- Compression Set: <10% after 24 hours at 70°C

2. Types of Conductive Foam

1. Nickel-Coated Polyurethane Foam

- Most common type, provides 60-80 dB shielding effectiveness

- Excellent compression recovery (>90% after 100,000 cycles)

- Ideal for gasketing and EMI shielding applications

2. Carbon-Loaded Conductive Foam

- Lower cost alternative, surface resistance 1-10 Ω/sq

- No metal particles, suitable for medical applications

- Good for static discharge protection

3. Custom Hybrid Variants

Fire-resistant versions with UL94 V-0 rating

Multi-layer constructions with adhesive backing

Combination with non-woven materials for directional conductivity

Click to view products:Conductive Foam

3. Performance Characteristics

| Parameter | Standard Range | Importance |

|---|---|---|

| Shielding Effectiveness | 60-100 dB @1GHz | EMI protection level |

| Surface Resistance | 0.01-10 Ω/sq | Conductivity performance |

| Compression Force | 0.5-5.0 psi | Sealing capability |

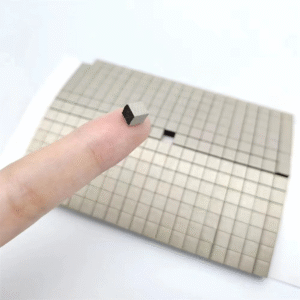

| Thickness Range | 1-10 mm | Application flexibility |

| Peel Strength | 10-40 N/25mm | Adhesion performance |

4. Industry Applications

Electronics Manufacturing

- 5G device shielding: Requires >80 dB effectiveness at 6GHz

- Server rack EMI protection: Needs compression set <15%

- PCB grounding: Surface resistance <0.1 Ω/sq

Automotive Electronics

- Battery management systems: Must withstand vibration and temperature cycling

- ADAS sensor shielding: Requires consistent performance in harsh environments

Medical Equipment

- MRI room shielding: Non-magnetic properties essential

- Wearable devices: Needs biocompatible materials (ISO 10993)

5. Selection Guidelines

For High-Frequency Applications: Choose fine-pore foam with dense metal plating

For Vibration Environments: Select high-recovery polyurethane base

For Cost-Sensitive Projects: Consider carbon-loaded alternatives

For Medical Use: Specify nickel-free and halogen-free materials

6. Advanced Innovations

- Nanotechnology: Graphene-enhanced coatings for lower surface resistance

- Environmental Adaptability: Hydrophobic treatments for outdoor applications

- Smart Materials: Pressure-sensitive conductivity variations

7. Quality Standards

MIL-PRF-83528: Military-grade performance standards

UL 94: Flame retardancy certification

ISO 9001: Quality management system

RoHS/REACH: Environmental compliance