The Silent Enemies of Perfection: Understanding Burrs & Adhesive Ooze 🔍

In the world of precision die cutting, two common adversaries threaten component quality: microscopic burrs and unwanted adhesive ooze. These seemingly minor defects can cause major headaches in automated assembly, affect product aesthetics, and compromise functional performance.

⚔️ CONQUERING BURRS: The Sharp Edge Solution

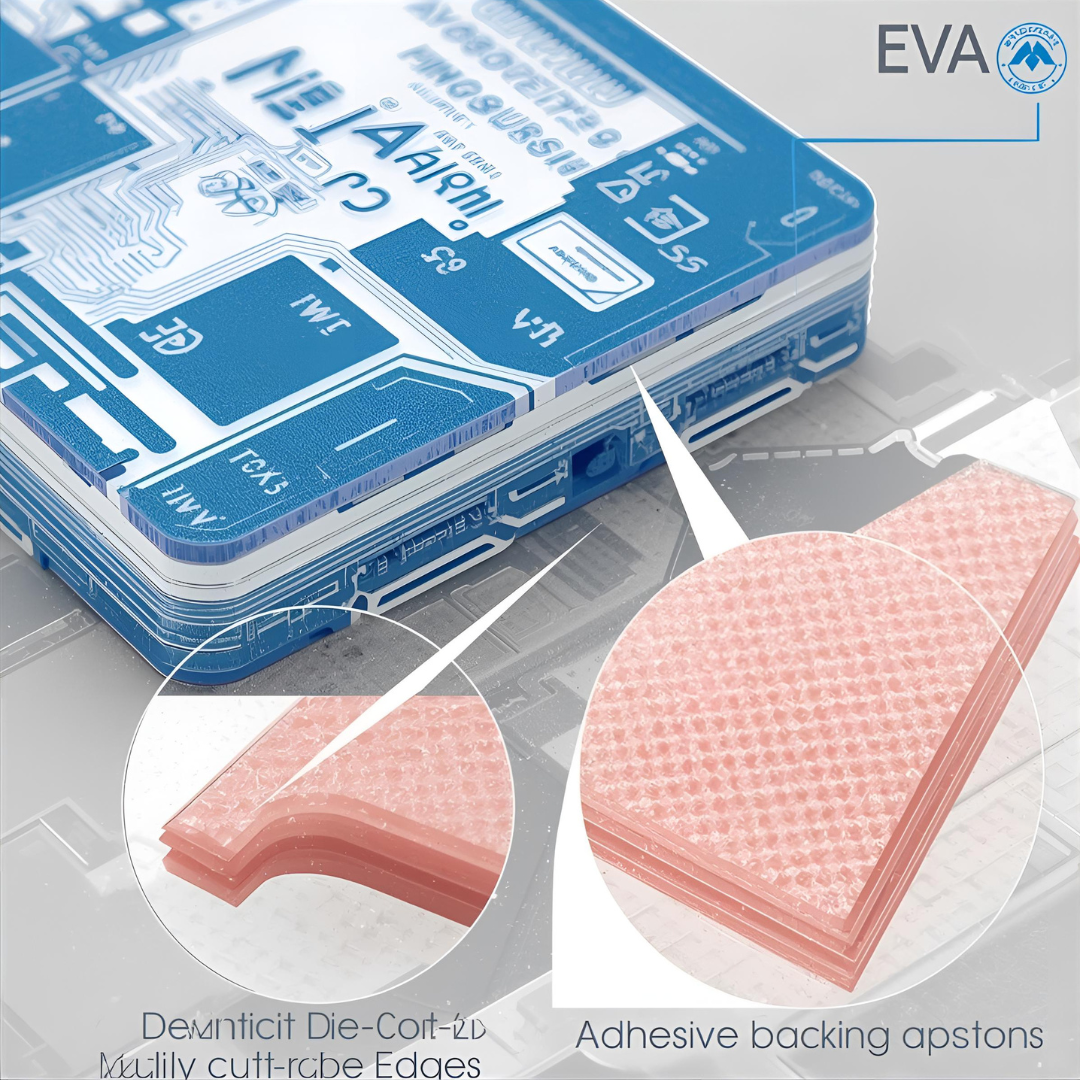

Understanding Burr Formation:

- Dull tooling creating torn edges instead of clean cuts

- Incorrect die pressure causing material deformation

- Improper material selection for specific cutting methods

- Machine misalignment producing inconsistent results

Advanced Solutions for Flawless Edges:

1. PRECISION TOOLING MASTERY:

- Laser-hardened steel rules maintaining sharpness 5x longer

- Custom blade angles optimized for specific material types

- Progressive die systems for multi-stage processing

- Digital laser cutting for burr-free complex geometries

2. MATERIAL-SPECIFIC STRATEGIES:

- Polyimide films requiring specialized coating techniques

- Adhesive tapes needing precise temperature control

- Foam materials benefiting from cryogenic stabilization

- Composite layers demanding customized blade configurations

🛡️ TAMING ADHESIVE OOZE: The Clean Edge Revolution

Root Causes of Adhesive Migration:

- Excessive pressure during conversion processes

- Temperature fluctuations affecting adhesive viscosity

- Incorrect liner selection failing to contain adhesive flow

- Improper storage conditions compromising material integrity

Professional Ooze Prevention Methods:

1. ADVANCED ADHESIVE MANAGEMENT:

- Precision coating technology ensuring uniform adhesive distribution

- Custom formulation expertise matching adhesive to application needs

- Liner barrier optimization creating perfect containment systems

- Environmental controls maintaining ideal processing conditions

2. PROCESS PERFECTION TECHNIQUES:

- Kiss-cutting mastery achieving perfect depth control

- Temperature-regulated tooling preventing adhesive activation

- Strategic waste matrix design containing potential ooze zones

- Inline inspection systems detecting microscopic imperfections

⭐ The Quality Assurance Advantage

Our Multi-Layer Inspection Protocol:

- Microscopic edge analysis at 50x magnification

- Adhesive integrity testing under extreme conditions

- Automated optical inspection for 100% quality verification

- Statistical process control ensuring consistent results

🚀 Real-World Success Stories

Medical Device Breakthrough:

Eliminated burrs on micro-scale diagnostic components through cryogenic laser cutting, achieving perfect edges for implantable medical devices.

Electronics Manufacturing Victory:

Solved adhesive ooze in smartphone display assembly using custom-formulated adhesives and precision temperature control, enabling flawless automated component placement.

💡 Your Path to Perfect Components

Achieving burr-free, ooze-free components requires more than good equipment—it demands deep expertise in:

MATERIAL SCIENCE:

- Understanding polymer behavior under stress

- Predicting adhesive flow characteristics

- Selecting optimal liner combinations

- Customizing solutions for unique applications

PROCESS ENGINEERING:

- Fine-tuning every manufacturing parameter

- Implementing real-time quality monitoring

- Developing customized tooling solutions

- Maintaining consistent environmental controls

🌟 Ready to Eliminate Quality Issues Forever?

Stop compromising on component quality. Our specialized expertise in precision edge perfection and adhesive containment technology ensures your parts meet the highest standards every time.

➡️ Request Your FREE Component Quality Assessment!

Our experts will:

- Analyze your current component challenges

- Provide specific recommendations for improvement

- Share case studies from similar applications

- Offer samples demonstrating perfect results

Transform your component quality from problematic to perfect with cutting-edge solutions and unparalleled expertise.

Contact our quality engineering team today and discover the difference precision makes!

Keywords Integrated: eliminating burrs, preventing adhesive ooze, die-cut components, precision die cutting, burr-free edges, adhesive containment, laser-hardened steel rules, digital laser cutting, polyimide films, kiss-cutting mastery, automated optical inspection, micro-scale components, implantable medical devices, smartphone display assembly, precision edge perfection, adhesive containment technology, quality engineering.