A Comprehensive Guide from Material Properties to Industry Applications

1. Fundamental Material Characteristics

Chemical Composition and Structure

- Ethylene-Vinyl Acetate Copolymer (EVA), Vinyl Acetate (VA) content: 5%-40%

- Closed-cell foam structure, density range: 0.03-0.25 g/cm³, customizable hardness (Shore C 15-80)

Key Physical Properties

| Property | Value Range | Industry Impact |

|---|---|---|

| Reboundedness | 40%-65% | Determines cushioning performance |

| Compression Set | 10%-35% (22h@70°C) | Impacts service life |

| Temperature Resistance | -50°C to 80°C | Applicable environment range |

| Water Absorption | <1% | Key waterproof property |

| Tear Strength | 3-8 kN/m | Mechanical durability indicator |

2. Special Modified Varieties

- Anti-Static EVA

- Surface resistance: 10^6-10^9Ω, for electronic product packaging

- Added carbon nanotubes or permanent anti-static agents

- Flame-Retardant EVA

- UL94 V-0 rating, oxygen index >28%

- Aluminum/Magnesium hydroxide composite flame retardant system

- High-Rebound EVA

- Reboundedness >60%, for sports shoe midsoles

- Peroxide cross-linking foaming technology

3. In-Depth Industry Applications

New Energy Vehicle Sector

- Battery cushion pads: Thermal conductive EVA (0.6-1.2 W/m·K)

- Requirements: UL94 V-0 rating, resistant to coolant corrosion

Medical Device Applications

- Medical device packaging: Complies with ISO 11607 requirements

- Surgical positioning pads: Biocompatibility testing (ISO 10993)

High-End Sports Equipment

Surfboard filling: Closed-cell ratio >90%, excellent waterproofness

Sports shoe midsoles: Energy return rate >65%

4. Processing Technology Comparison

| Process Type | Applicable Products | Min Thickness | Tolerance Control |

|---|---|---|---|

| Compression Molding | Footwear/Sporting Goods | 2mm | ±0.3mm |

| Continuous Extrusion | Rolls/Sheets | 0.5mm | ±0.15mm |

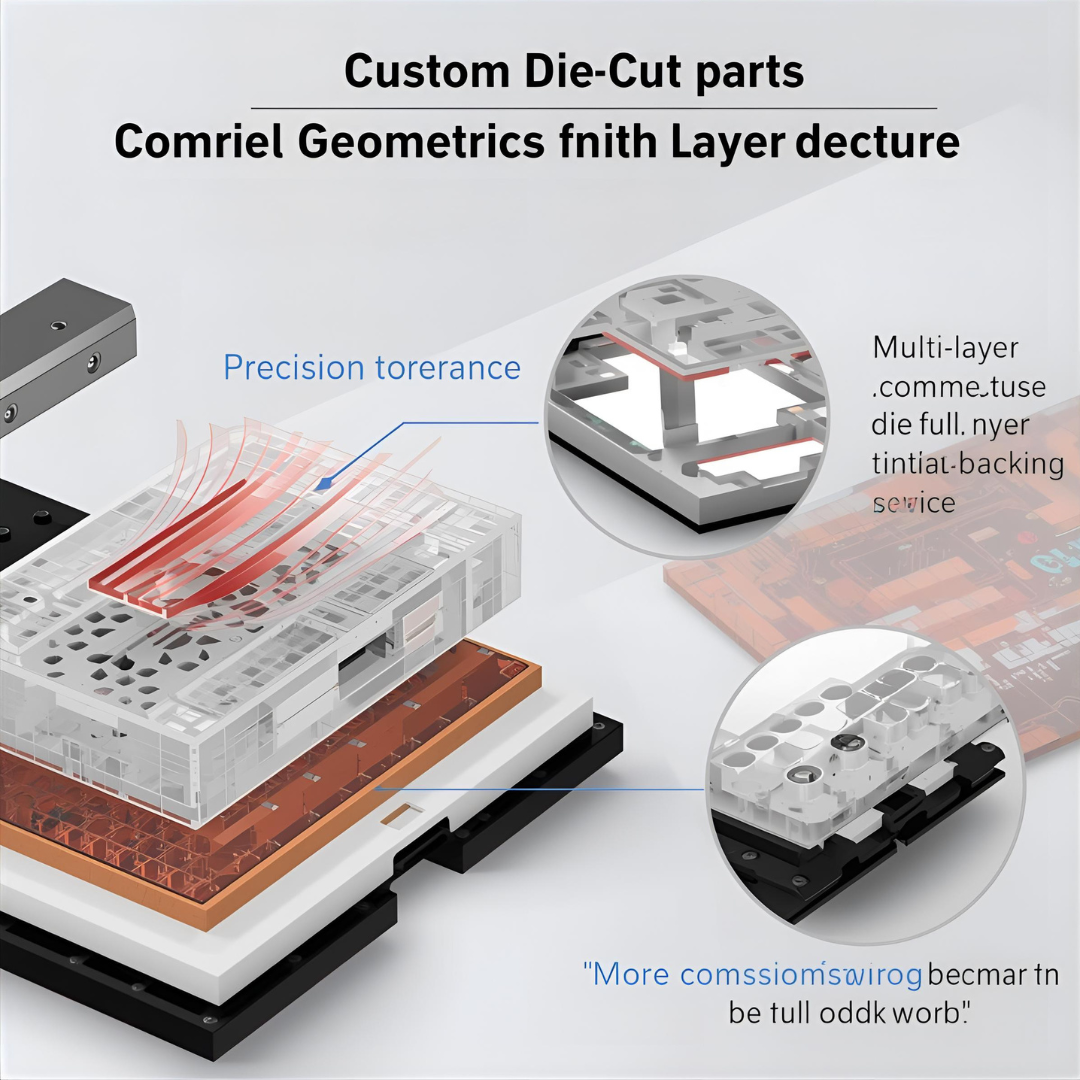

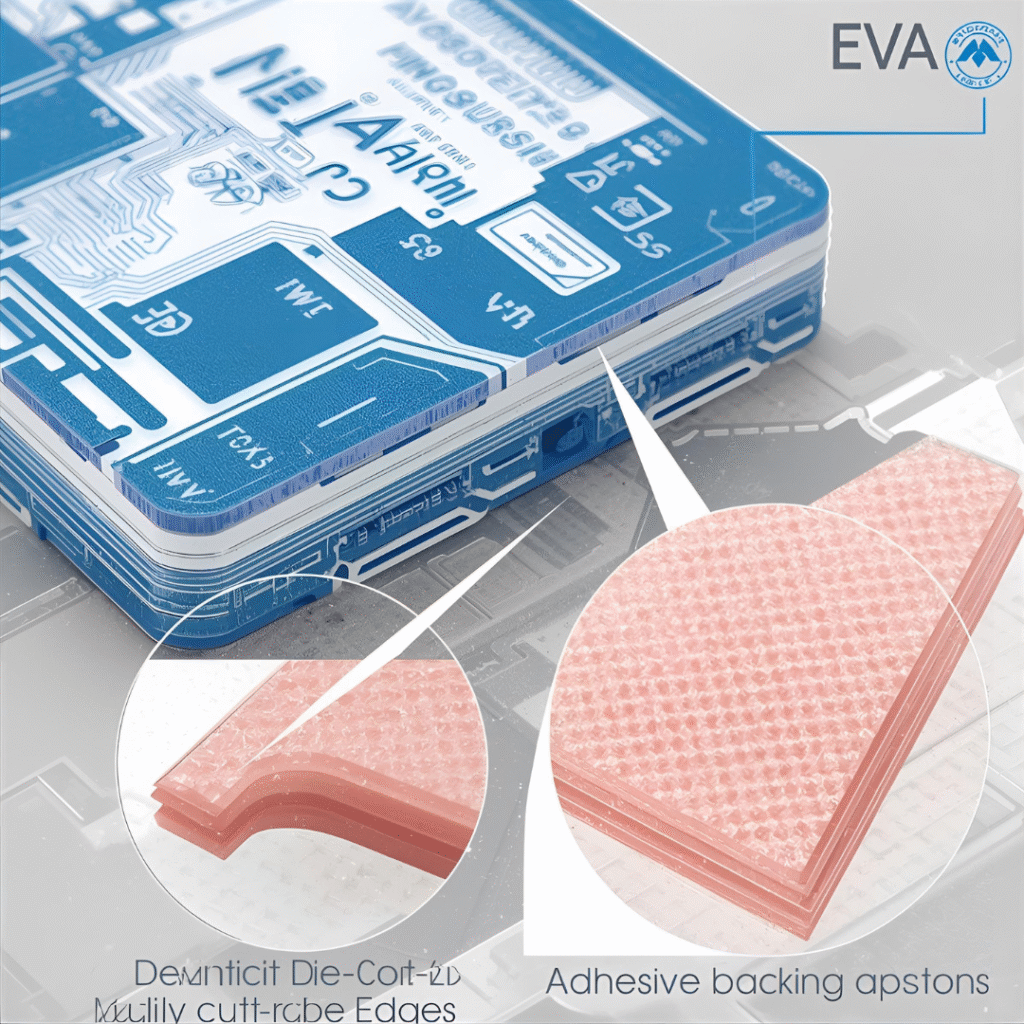

| Precision Die-Cutting | Electronic Gaskets | 0.3mm | ±0.1mm |

5. Quality Control Standards

- Automotive Industry: IATF 16949 system, PPAP certification

- Medical Industry: ISO 13485, biocompatibility testing

- Electronics Industry: ESD S20.20 anti-static standard

6. Technology Development Trends

Smart Manufacturing: AI visual inspection of cell uniformity

Green Environmental Protection: Bio-based EVA (sugarcane ethanol extraction)

Functional Integration: Thermal conductive-flame retardant-EMI shielding multifunctional composites

Click to view products:EVA Foam

Products by Category

-

Custom Black EVA Foam Pads – Reusable Self-Adhesive Feet with Odorless Flexible Design

-

Custom EVA Foam Tape – Waterproof Single-Sided High Adhesion from Manufacturer

-

Custom Multi-Color EVA Foam Sheets – Adhesive Backed for Crafts & Industrial Use

-

Non-Slip EVA Foam Pads – Solid Color Bath/Bedroom Floor Mats with Easy-Clean Surface