Designing a component for precision die cutting? A perfect design on your CAD screen doesn’t always translate to a perfect physical part. Even minor oversights can lead to major production headaches, including assembly failures, inflated costs, and project delays.

At DieCutChina, we’ve reviewed thousands of designs. The same design for manufacturing (DFM) pitfalls appear again and again. This guide exposes these common errors and provides actionable solutions to ensure your custom adhesive tapes and foam gaskets perform flawlessly.

❌ MISTAKE #1: Ignoring Material Directionality (The “Grain”)

The Problem: Many engineers treat flexible materials like isotropic solids. However, materials like double-sided tapes, PET films, and certain foams have a machine direction (MD) and transverse direction (CD). This can cause parts to stretch, shrink, or crack inconsistently after cutting.

✅ The Solution: Always consult with your die-cutting supplier about material grain during the prototyping phase. They can nest your parts optimally on the roll to ensure dimensional stability and consistent performance in the final application.

💥 MISTAKE #2: Specifying Impossible Tolerances

The Problem: Demanding a tolerance of ±0.01mm on a part that only requires ±0.2mm is a classic error. Over-tolerancing dramatically increases cost and inspection time without adding functional value, especially for parts like EMI shielding gaskets or general-purpose padding.

✅ The Solution: Understand standard die cut tolerances. For most non-critical parts, ±0.15mm is standard and cost-effective. Reserve tighter tolerances (±0.05mm) only for micro-components or critical electronic insulation features. Discuss functional needs, not just CAD dimensions.

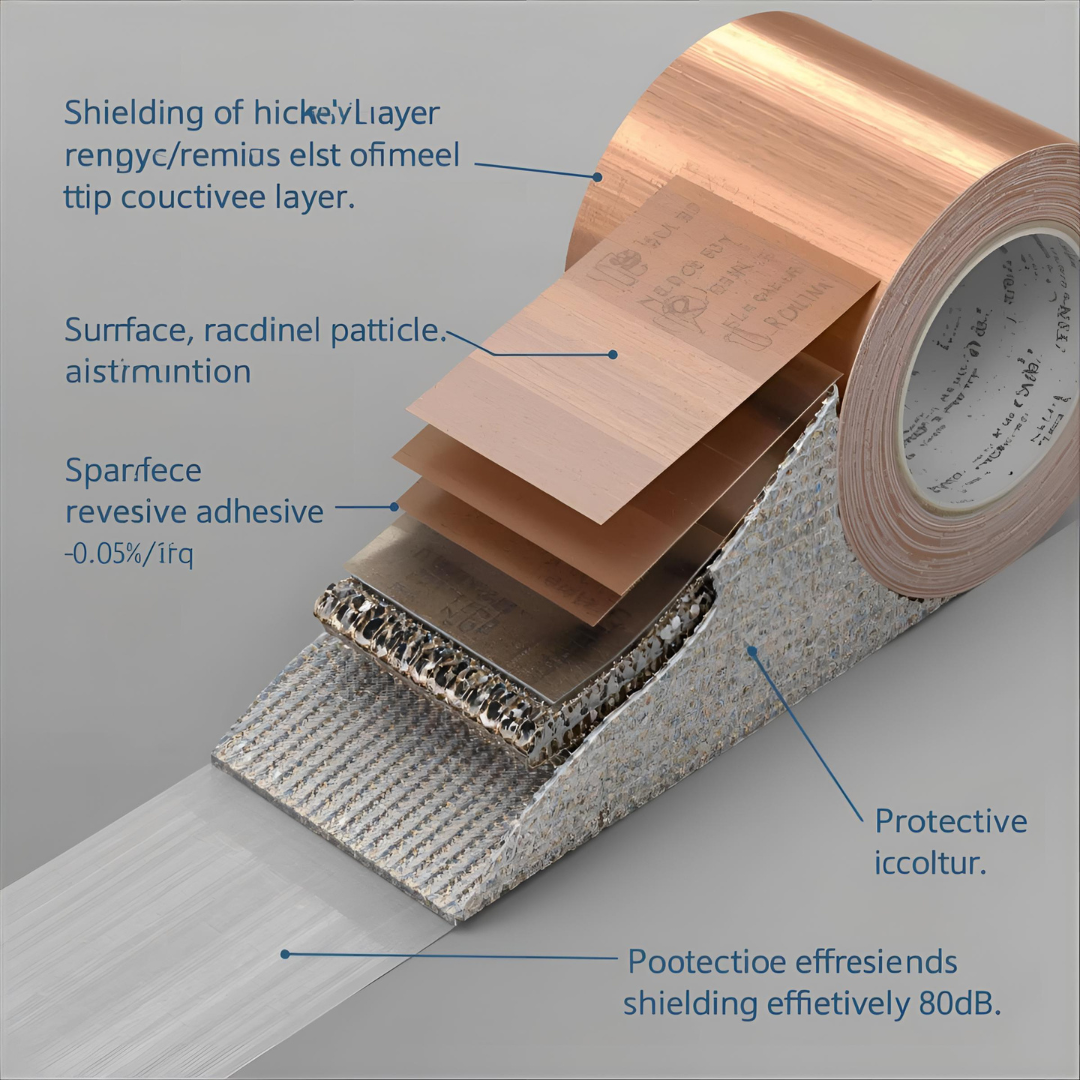

🔗 MISTAKE #3: Poor Adhesive Selection & Liner Confusion

The Problem: Simply specifying “double-sided tape” is a recipe for failure. Will it bond to low-surface-energy plastics? Does it need high-temperature resistance? Further, forgetting to specify liner type (paper, film, differential) can cause dispensing nightmares in automated assembly.

✅ The Solution: Be specific about the substrate and environment. We offer a vast library of pressure-sensitive adhesive tapes, from VHB tape alternatives for strong bonding to silicone adhesives for extreme heat. Our engineers can guide you to the perfect material.

Explore our adhesive solutions here: [Link to Adhesive Category – https://diecutchina.com/offerings/]

📐 MISTAKE #4: Designing Sharp Internal Corners

The Problem: A sharp 90-degree internal corner on a CAD model is geometrically clean. However, a physical die cannot cut a perfect sharp internal corner. This forces a suboptimal “overburn” that weakens the material and often creates a tear point.

✅ The Solution: The golden rule of die cut gasket design is to specify a radius on all internal corners. A radius as small as 0.5mm allows the die to cut cleanly, prevents tearing, and dramatically extends the tool’s life, reducing your part cost.

📦 MISTAKE #5: Overlooking the “Kiss” vs. “Through-Cut” Decision

The Problem: Failing to communicate how the part should be presented for assembly halts production lines. Should the part be on a roll for automated application (kiss cutting), or as individual pieces in a bag (through-cutting)?

✅ The Solution: Clearly define the part’s destination early in the custom die cutting process. For automated assembly of custom adhesive parts, kiss-cutting is almost always required. This is a critical piece of information for your manufacturer.

✨ Your Blueprint for Flawless Parts

Avoiding these mistakes separates a successful project from a frustrating one. The single most powerful solution is early collaboration with your manufacturing partner.

Don’t let a design error cost you time and money.

➡️ Submit Your Design for a FREE DFM (Design for Manufacturability) Analysis!

Our engineering team will review your drawings and identify potential issues before you tool up, ensuring a smooth path to production.

📧 Get Your Free Design Review & Quote Today!

[Link to Contact Page – https://diecutchina.com/contact/]

Keywords Integrated: die-cut part design, design for manufacturing, DFM, custom adhesive tapes, foam gaskets, die cut tolerances, precision die cutting, kiss cutting, pressure-sensitive adhesive tapes, VHB tape alternatives, silicone adhesives, die cut gasket design, custom die cutter, die-cutting supplier, prototyping phase, electronic insulation, EMI shielding gaskets.