Welcome to the world of precision die cutting! If you’ve ever wondered how complex, adhesive parts in your smartphone or the delicate EMI shielding gaskets in a medical device are made, you’ve found the right guide. This isn’t just about cutting shapes; it’s about manufacturing critical components with microscopic accuracy. Let’s demystify the process, one step at a time. ✅

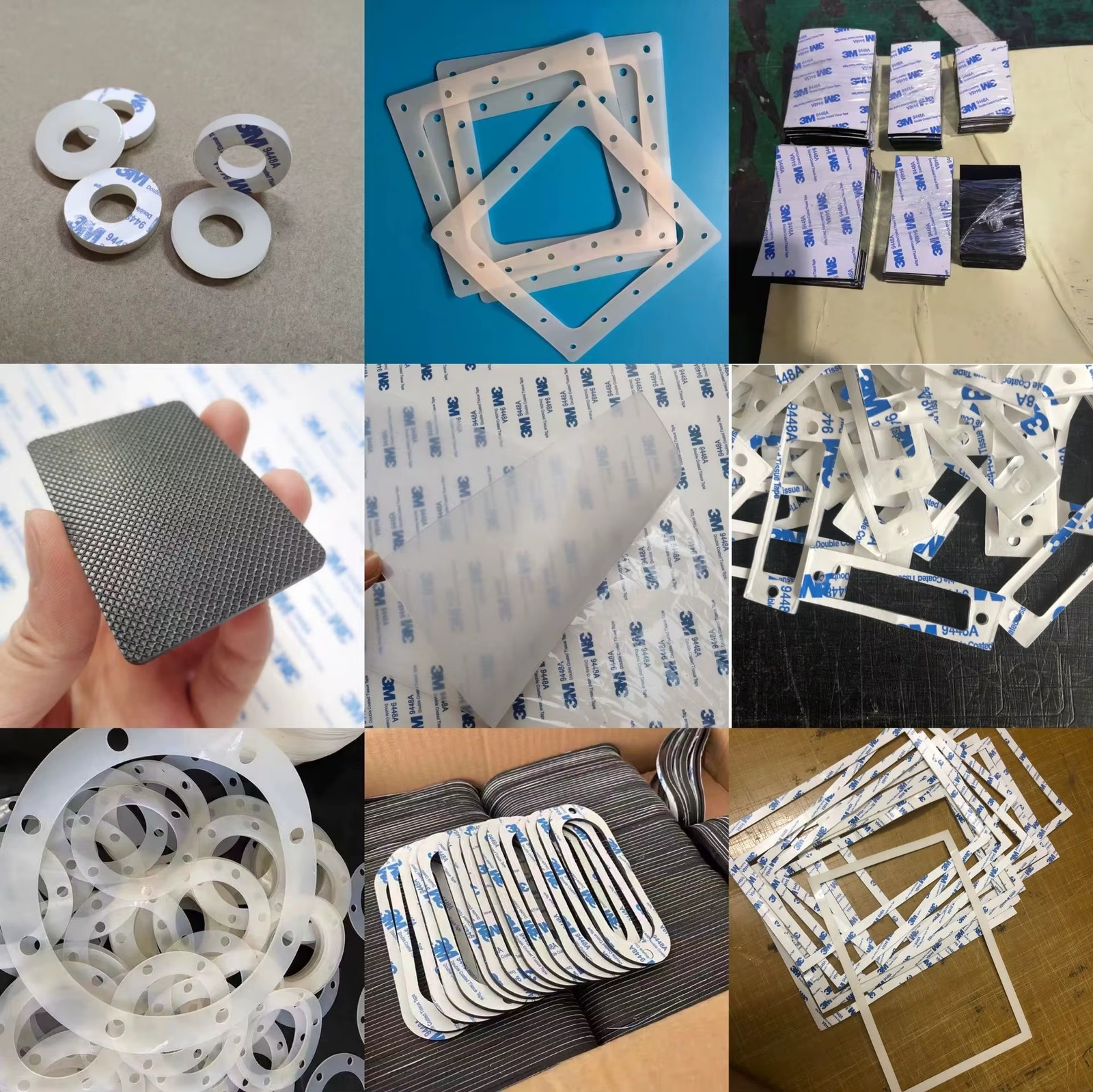

Precision die cutting is a specialized manufacturing process that converts flexible materials—adhesives, films, foams, and foils—into exact, repeatable shapes using a precision-made tool, known as a die. It’s the secret behind millions of reliable components in electronics, automotive, and healthcare.

📌 The Building Blocks: Core Materials in the Die Cut Universe

The material is the soul of your component. Selecting the right one is non-negotiable.

- Adhesive Films & Tapes: This includes everything from double-sided adhesive tape for mounting to single-sided liner products for protection. Think PET double-sided tape for strong bonding or non-conductive thermal tapes for heat management.

- Plastic Films & Insulators: Materials like Polyimide (PI) films (Kapton) for high-temperature insulation and PET insulating sheets are staples for electronic insulation.

- Foams & Cushioning Materials: From PORON foam for shock absorption to conductive foam for static protection, these are vital for padding and gasketing.

- Specialty Composites: This includes thermal interface materials (like graphite pads) for cooling and EMI/RFI shielding materials to protect sensitive electronics from interference.

Discover our vast material library for your project: [Link to Product Page – e.g., https://diecutchina.com/offerings/]

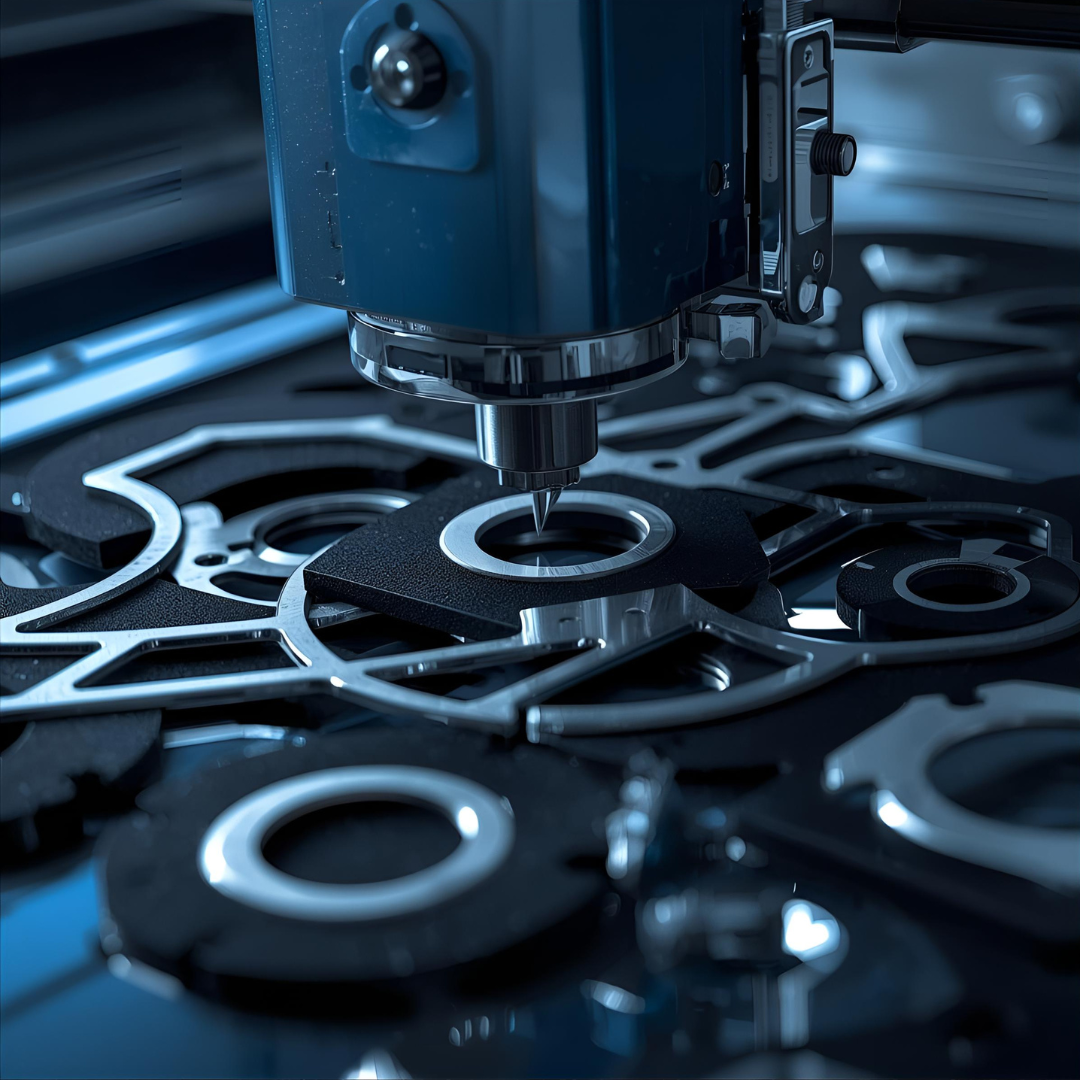

⚙️ The Precision Dance: A Peek into the Die Cutting Process

How does a roll of material become a precision part? The journey is a marvel of engineering.

- Design & Die Creation: It all starts with your dieline (the digital outline). We engineer the most efficient way to cut your part, considering material grain and waste. A custom tool—a precision die—is fabricated. For prototypes, laser cutting offers incredible flexibility without tooling costs. ✨

- The Conversion Stage: The material roll is loaded into a precision die cutting machine. The die is pressed into the material with immense, controlled force, shearing it perfectly. For high-volume orders, rotary die cutting offers unparalleled speed and efficiency.

- Kiss-Cutting & Through-Cutting: A critical distinction! Kiss cutting delicately cuts through the top material but leaves the backing liner intact, allowing for easy automated dispensing. Through-cutting cuts through the entire thickness, producing individual pieces.

- Stripping & Inspection: The excess material (matrix) is stripped away, leaving only the desired parts. Each batch undergoes rigorous inspection to ensure it meets specified die cut tolerances.

🎯 The Devil’s in the Details: Understanding Tolerances & Capabilities

“Precision” is measured in numbers. Here’s what you need to know:

- Standard Tolerance: For most parts, a standard tolerance of ±0.15mm is achievable and cost-effective.

- High-Precision Tolerance: With advanced equipment and controlled processes, we can hold tolerances as tight as ±0.05mm for micro-components.

- Key Influencers: Material stability, tooling precision, and machine calibration all impact the final tolerance. This is why partnering with an expert custom die cut manufacturer is crucial for complex applications.

🚀 Launch Your Project with Confidence

Navigating die cut gasket design or sourcing custom EMI shielding parts doesn’t have to be daunting. With the right partner, it’s a seamless journey from concept to mass production.

Have a design or an idea? Our engineering team is ready to provide a free design-for-manufacturability (DFM) analysis.

📩 Contact Us Today for a Free Project Review & Quote!

Let’s transform your design into a precision-made reality.

[Link to Contact Page – e.g., https://diecutchina.com/contact/]

Keywords Integrated: precision die cutting, custom die cutting process, die cut tolerances, die cut gasket, custom die cut parts, adhesive tape converter, EMI shielding gaskets, PET films, Polyimide films, electronic insulation, laser cutting, kiss cutting, rotary die cutting, precision die, custom die cut manufacturer, double-sided adhesive tape, thermal interface materials.