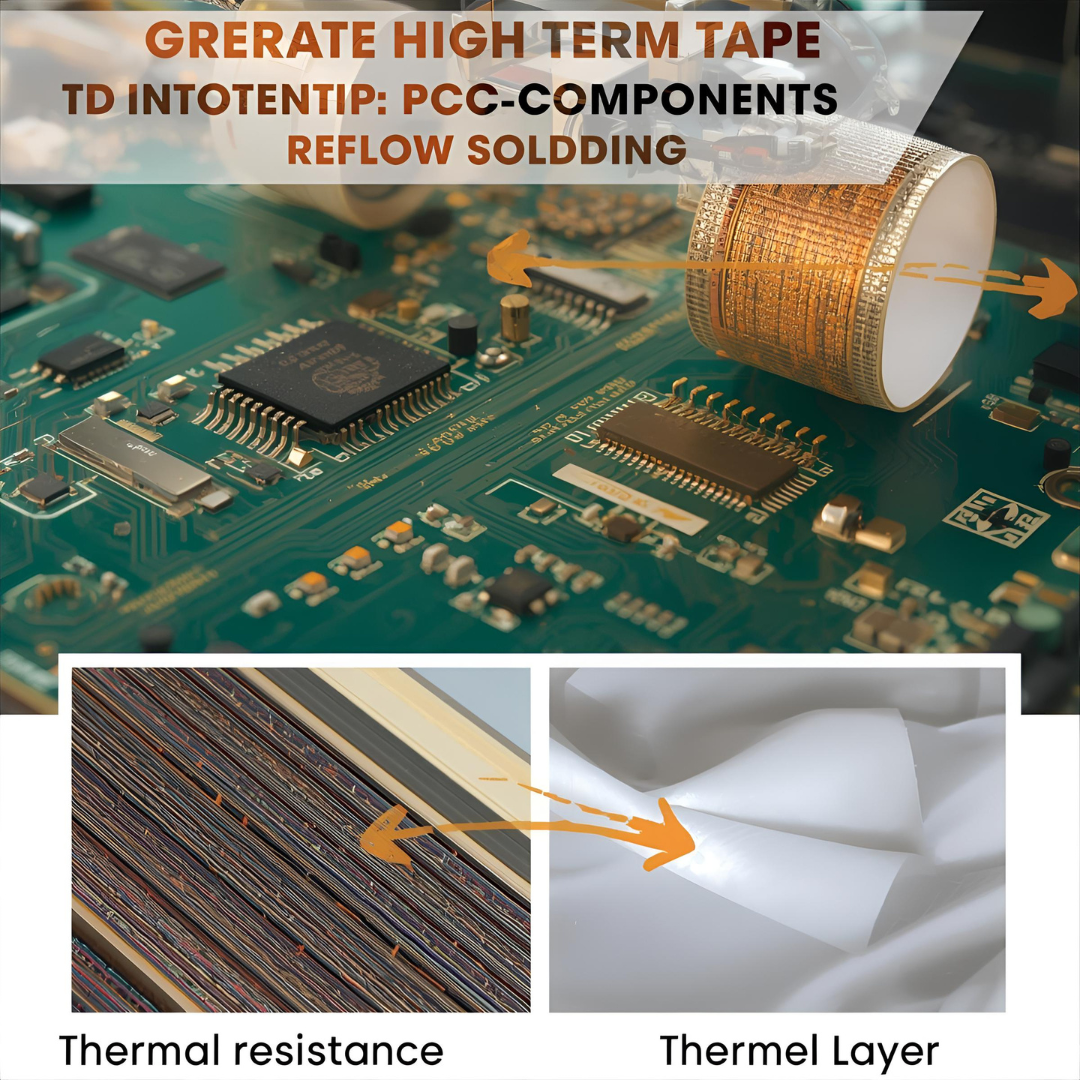

High-Temperature Tapes for Masking During Electronic Conformal Coating

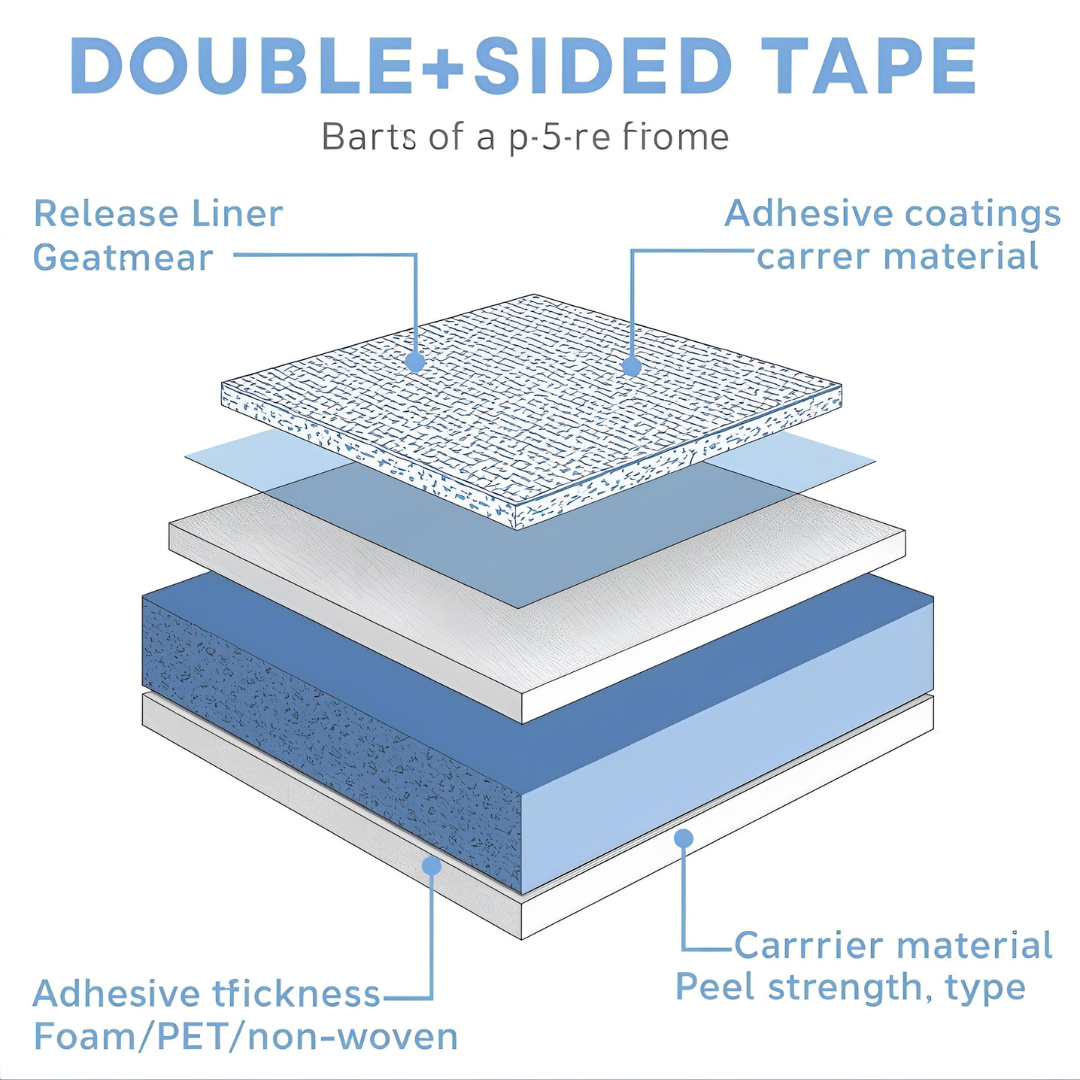

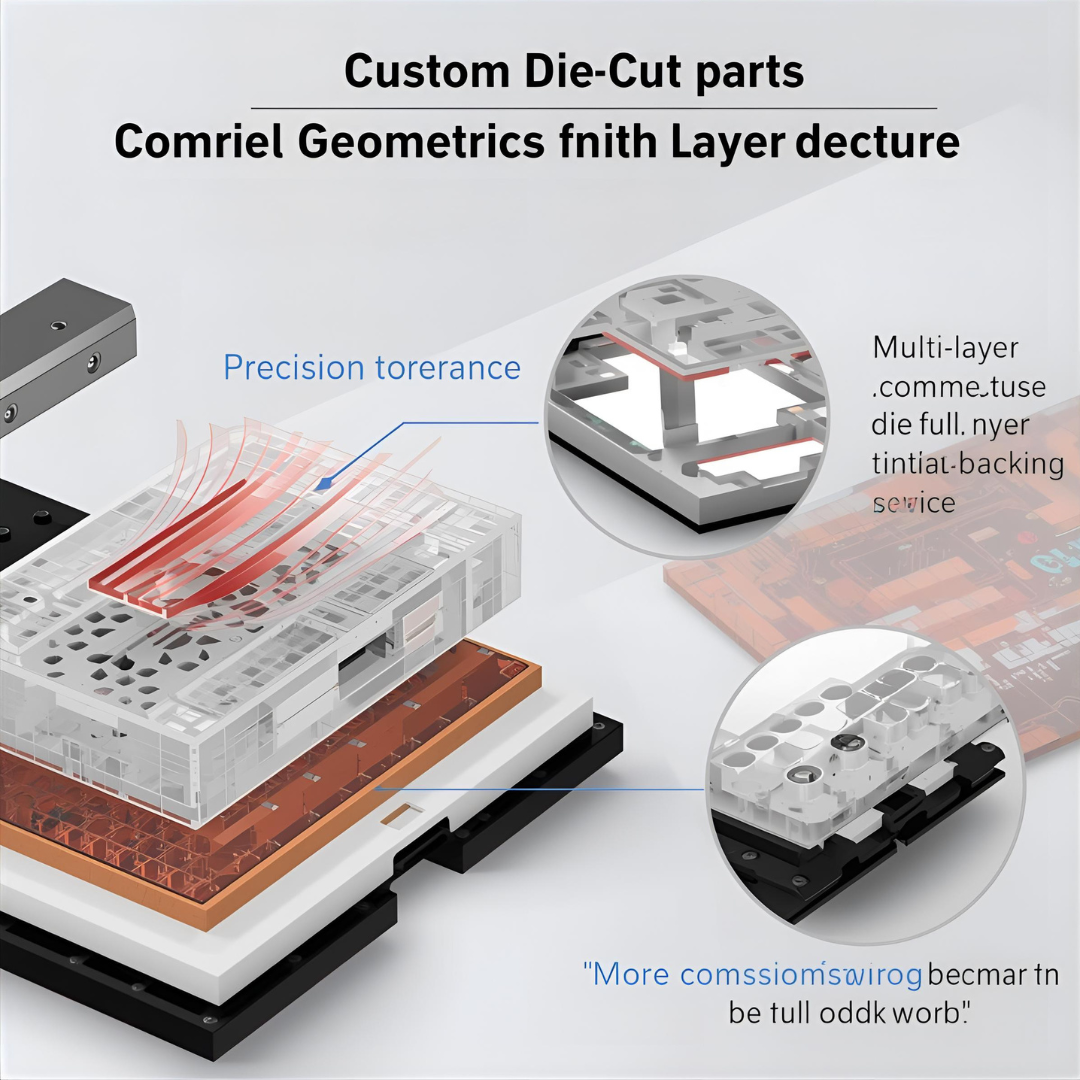

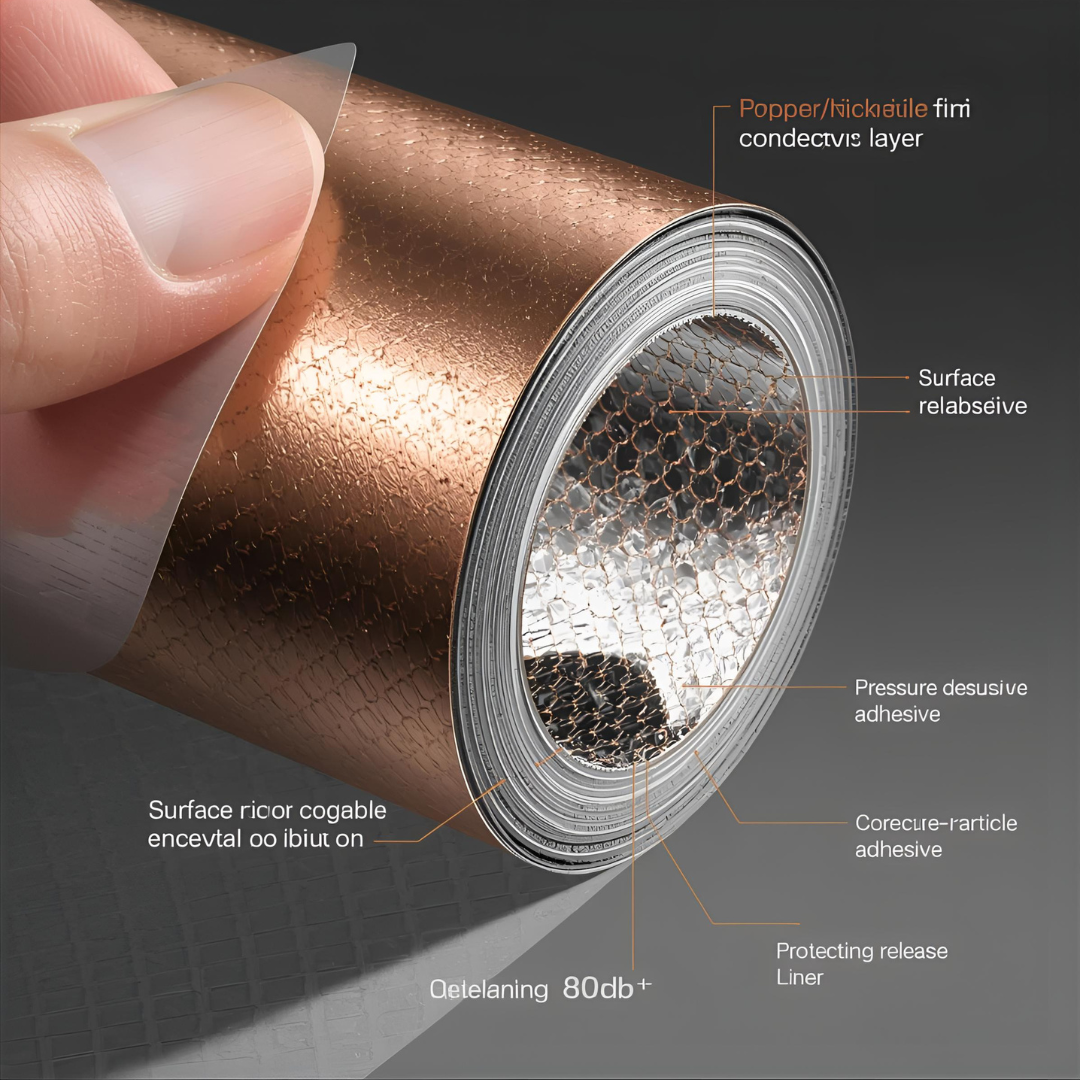

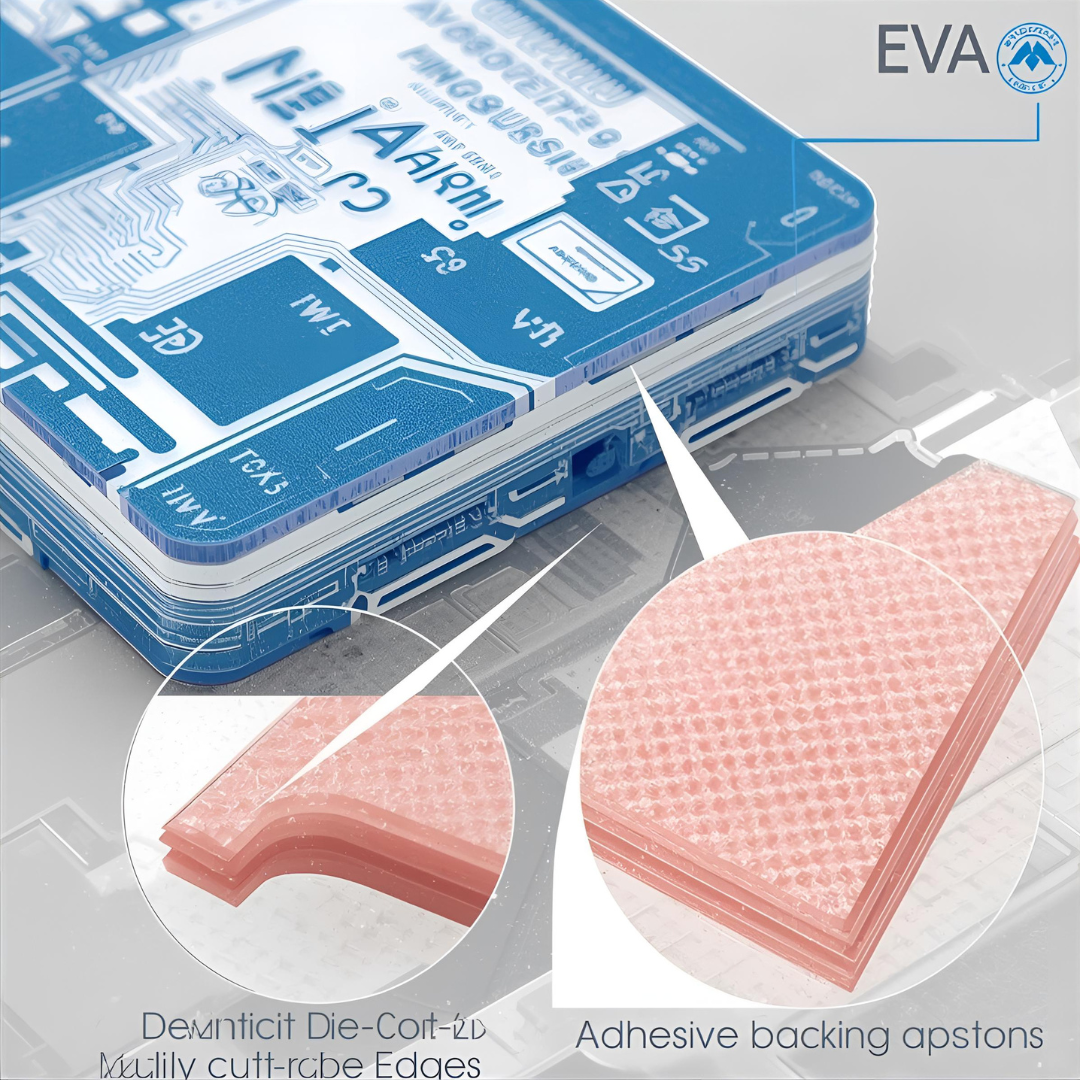

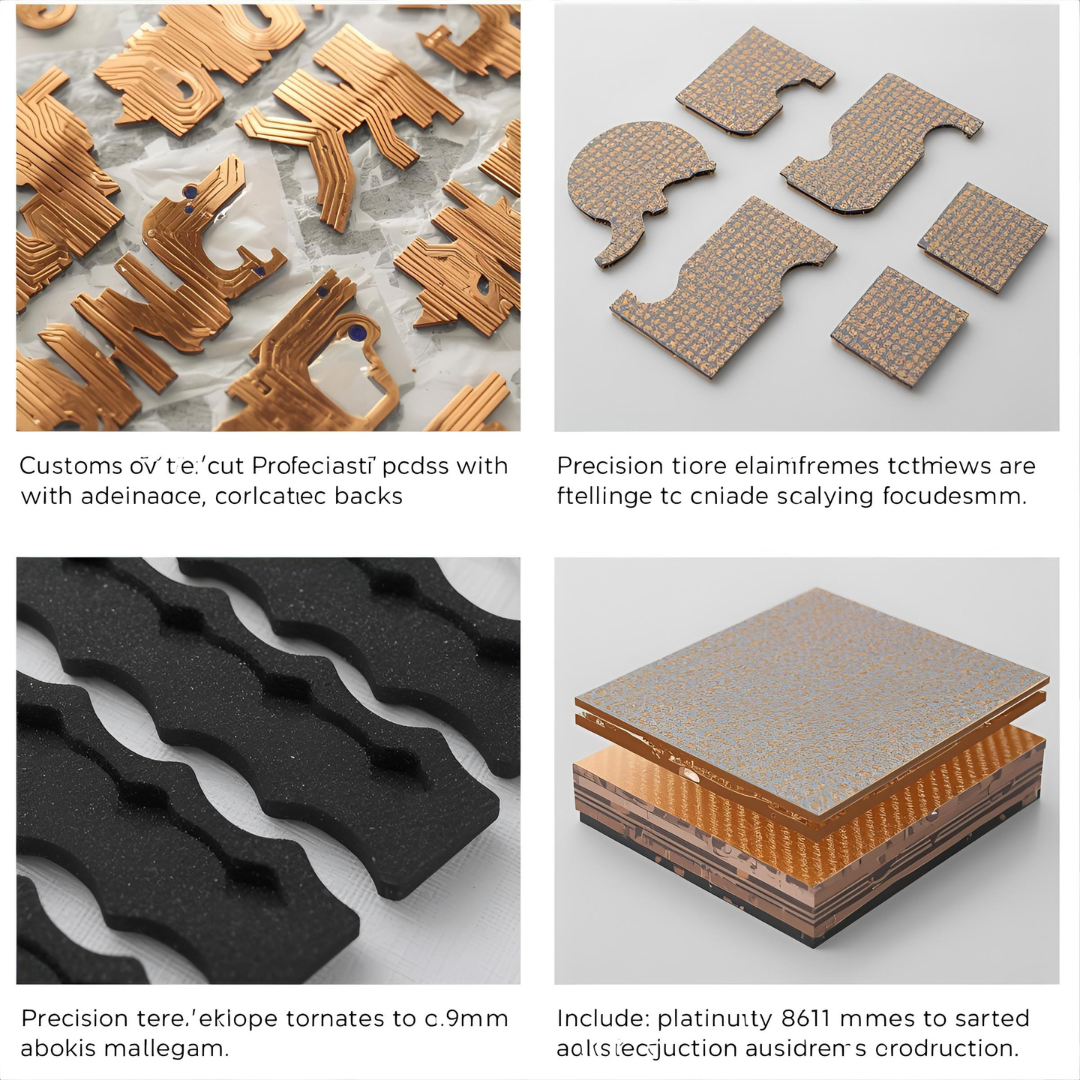

Precision Masking Excellence: High-Temperature Solutions for Conformal Coating 🖌️ Electronic conformal coating processes require high-temperature masking tapes that withstand curing temperatures while providing sharp, clean edges, easy removal, and residue-free performance for precision PCB protection. 📊 Conformal Coating Masking Performance Coating Type Cure Temperature Masking Time Tape Temperature Removal Cleanliness Acrylic 60-80°C 15-30 min Up to 120°C Excellent Silicone […]