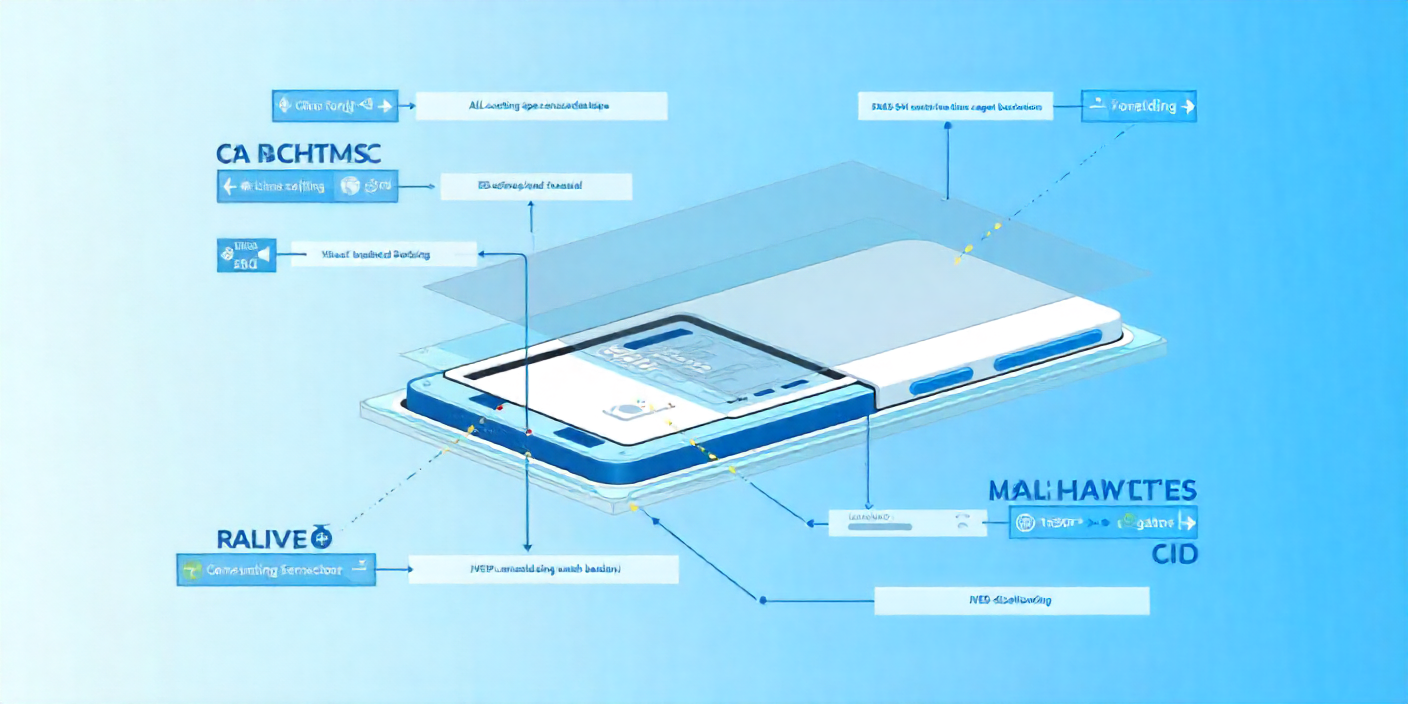

Custom Die-Cut Solutions: Precision Conductive Tape Applications for Unique Designs

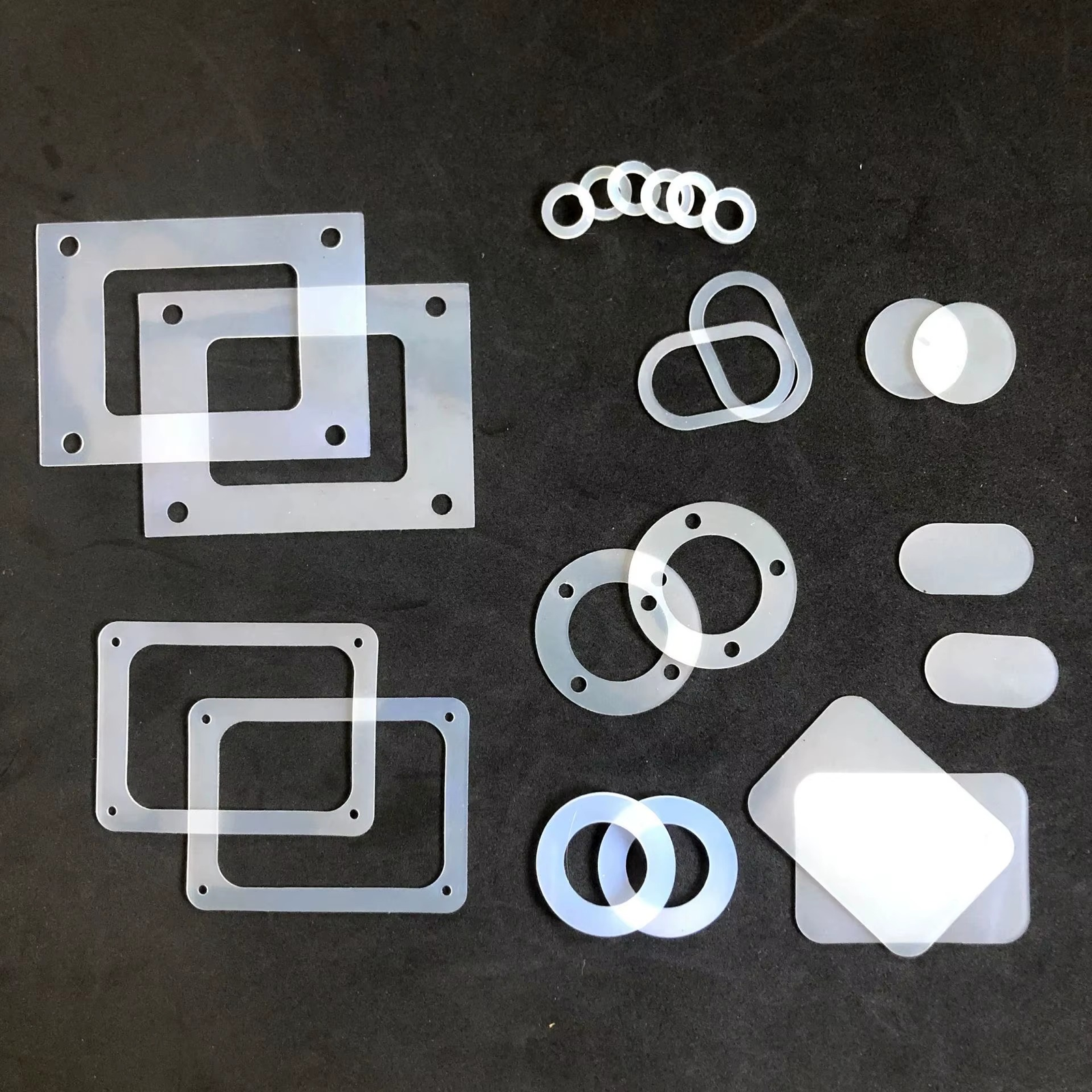

Precision Engineering: Custom Die-Cut Solutions for Unique Applications 🎯 Unique design requirements demand custom die-cut conductive tape solutions that deliver precise geometries, exact material specifications, and optimized performance for specialized applications across all industries. 📊 Customization Capabilities Matrix Capability Type Precision Level Minimum Feature Size Material Options Lead Time Kiss Cutting ±0.1 mm 0.5 mm All conductive materials 2-4 […]