Sealing and Bonding Solutions for Solar Panel Framing and Junction Boxes

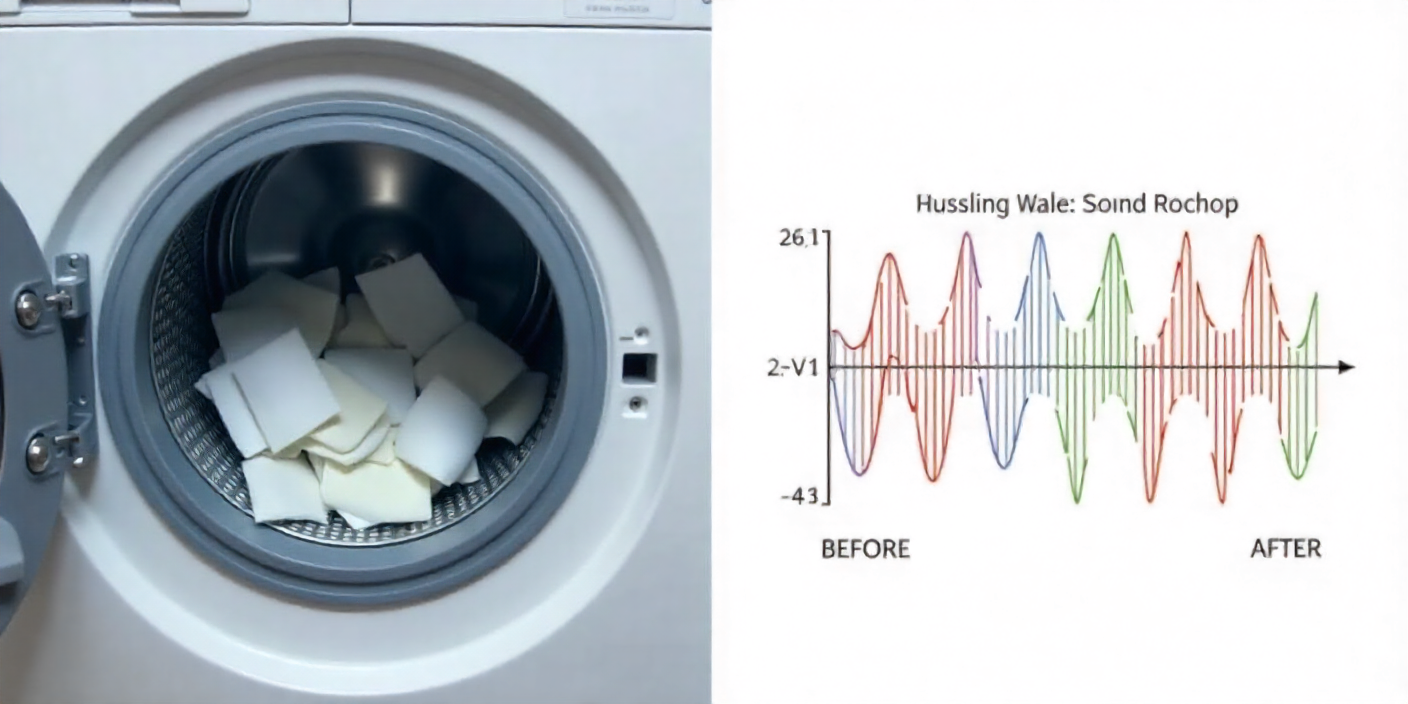

Solar Reliability: Advanced Sealing for Renewable Energy Systems 🌞 Solar panel installations demand specialized sealing and bonding solutions that provide weatherproof protection, structural integrity, and long-term reliability for framing systems and electrical junction boxes in outdoor environments. 📊 Solar Application Performance Component Sealant Type Temperature Range UV Resistance Service Life Panel Framing Structural Tape -40°C to 90°C 25+ years […]