Thermal Interface Materials with Electrical Insulation for EV Battery Packs

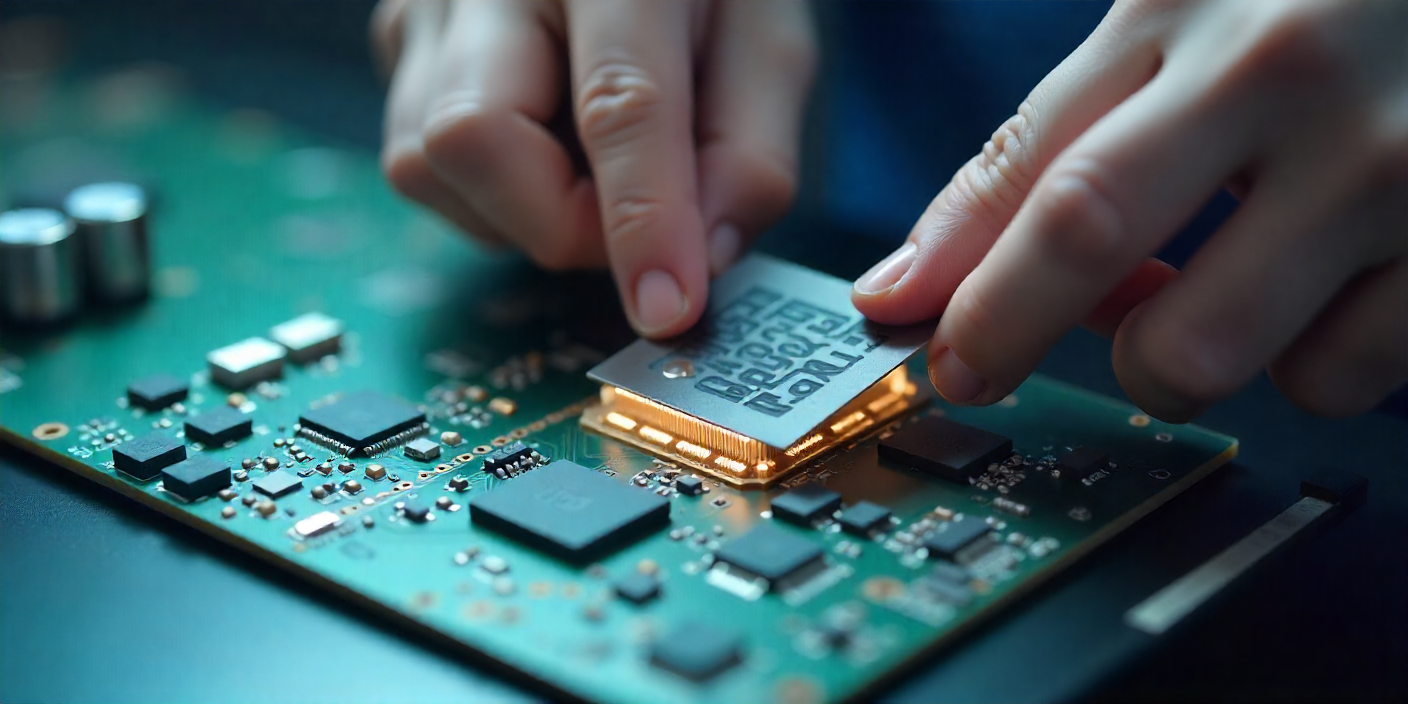

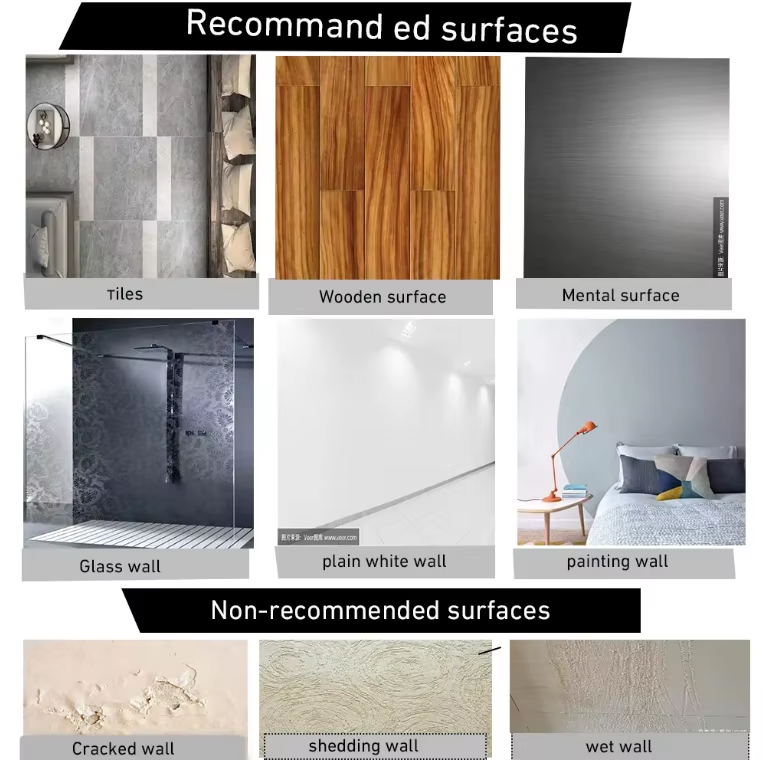

Thermal Interface Materials with Electrical Insulation for EV Battery PacksAdvanced Thermal Management Solutions for Next-Generation Electric Vehicles 🔋 Dual-Function Performance for EV Battery Systems Modern electric vehicle battery packs require sophisticated thermal interface materials that provide both efficient heat dissipation and reliable electrical insulation to ensure safety and performance in demanding automotive applications. 🚗 Technical Performance Matrix Characteristic Standard TIMs EV-Specialized […]