Why Proper Insulation is NON-Negotiable in Modern Electronics ✨

In today’s high-density electronics and powerful motor applications, electrical insulation does more than just prevent shorts—it manages heat, provides mechanical protection, and ensures long-term reliability. Precision die-cut insulating materials have become the unsung heroes in everything from electric vehicle motors to wearable medical devices.

📊 The Insulation Material Spectrum: Finding Your Perfect Match

Choosing the wrong insulating material can lead to catastrophic failure. Here’s your definitive guide to material selection:

🔥 POLYIMIDE (PI) FILMS – The High-Temperature Champion

- Continuous Rating: -269°C to +400°C

- Dielectric Strength: 5,000-7,000 V/mil

- Key Advantage: Exceptional thermal stability and chemical resistance

- Perfect For: Motor slot liners, PCB insulation, and high-temperature applications

💪 PET FILMS – The Cost-Effective Workhorse

- Temperature Range: -60°C to +130°C

- Dielectric Strength: 7,000 V/mil

- Key Advantage: Excellent balance of performance and affordability

- Ideal For: Consumer electronics, battery insulation, and general-purpose applications

🛡️ MYLAR® POLYESTER – The Reliable Performer

- Temperature Range: -60°C to +150°C

- Dielectric Strength: 7,500 V/mil

- Key Advantage: Superior moisture resistance and dimensional stability

- Best For: Transformer insulation, coil winding, and humid environments

🎯 Critical Applications: Where Precision Insulation Matters Most

ELECTRIC VEHICLE SYSTEMS:

- Battery Pack Insulation: Flame-retardant materials prevent thermal runaway

- Motor Phase Insulation: High dielectric strength films handle voltage spikes

- Power Electronics: Thermally conductive but electrically insulating pads

CONSUMER ELECTRONICS:

- PCB Insulation: Ultra-thin flexible films protect against shorts

- Battery Isolation: Puncture-resistant materials ensure safety

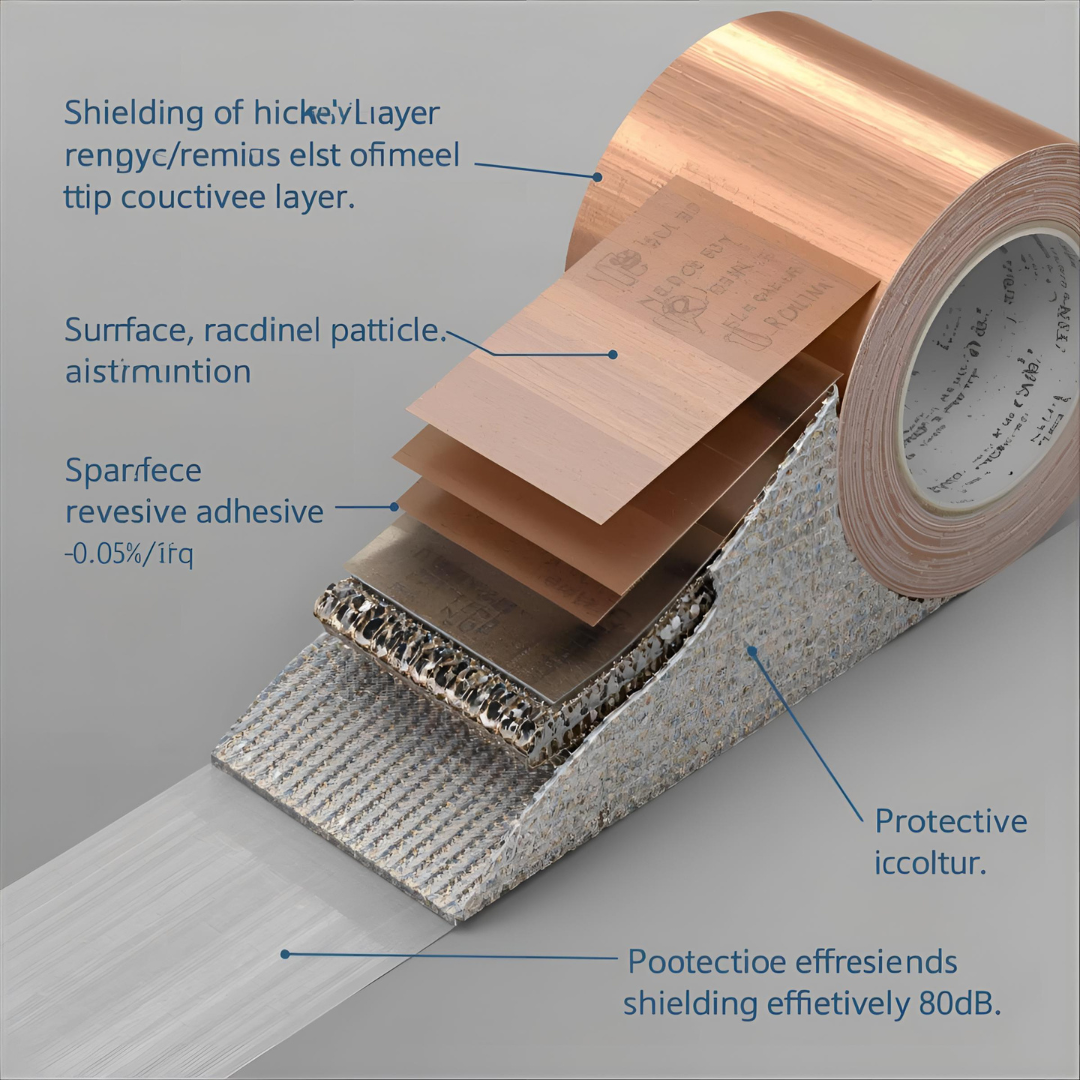

- EMI Shielding Grounding: Conductive/non-conductive combinations

⚡ The Die-Cutting Advantage: Why Shape Matters

Precision die-cutting transforms standard material rolls into high-performance components:

- Complex Geometries: Create intricate shapes for custom motor insulation

- Multi-Layer Laminations: Combine insulating and conductive layers

- Tight Tolerances: Achieve ±0.1mm precision for perfect fit

- Kiss-Cutting: Produce adhesive-backed insulation for easy installation

🚨 Common Insulation FAILURES & How to Avoid Them

THERMAL RUNAWAY:

- Problem: Material breaks down under high temperatures

- Solution: Upgrade to high-temperature PI films or ceramic-filled materials

DIELECTRIC BREAKDOWN:

- Problem: Insulation fails under voltage stress

- Solution: Increase material thickness or switch to higher dielectric strength films

MECHANICAL DAMAGE:

- Problem: Punctures or tears during assembly

- Solution: Use reinforced composite materials or toughened films

💡 Advanced Solutions: Beyond Basic Insulation

Today’s challenges require innovative approaches:

- Thermally Conductive Electrical Insulators: Manage heat while providing electrical isolation

- Hybrid Materials: Combine insulation with EMI shielding properties

- Custom Adhesive Systems: Ensure proper bonding in challenging environments

Discover our complete range of insulating solutions through our product portfolio.

🔧 Your Insulation Success Checklist

✅ Identify operating temperature range

✅ Determine voltage requirements

✅ Consider environmental factors (moisture, chemicals, UV)

✅ Evaluate mechanical demands

✅ Plan for assembly method

🌟 Ready to Solve Your Insulation Challenges?

Don’t let insulation be an afterthought. Our material experts specialize in matching the perfect die-cut insulating material to your specific electrical, thermal, and mechanical requirements.

➡️ Submit your application details for a FREE insulation material recommendation and sample kit.

Get expert guidance on selecting and manufacturing the ideal insulating components for your project.

Keywords Integrated: die-cut insulating materials, electronic insulation, motor insulation, PCB insulation, electrical insulation, polyimide films, PET insulation, high-temperature insulation, motor slot liners, battery insulation, thermal stability, dielectric strength, precision die-cutting, custom motor insulation, EMI shielding, thermally conductive insulation.