The Double-Sided Revolution: More Than Just Sticky on Both Sides ✨

Double-sided adhesive technologies have evolved far beyond simple sticky surfaces. Today’s advanced tapes represent sophisticated bonding solutions engineered for specific applications, materials, and environmental conditions. Understanding these technologies transforms tape selection from guessing to precision engineering.

🔬 The Adhesive Matrix: Choosing Your Chemical Champion

ACRYLIC-BASED ADHESIVES:

- High-performance applications requiring durability

- Excellent UV resistance for outdoor use

- Temperature tolerance from -40°C to 150°C

- Superior aging characteristics maintaining bond strength

RUBBER-BASED SYSTEMS:

- High initial tack for instant bonding

- Excellent flexibility conforming to uneven surfaces

- Cost-effective solutions for general purpose use

- Quick-stick properties for fast assembly

SILICONE FORMULATIONS:

- Extreme temperature performance up to 260°C

- Chemical resistance against solvents and oils

- Medical and food grade compliance options

- Excellent electrical insulation properties

📊 Backing Materials: The Structural Foundation

FOAM BACKINGS:

- Gap-filling capability compensating for uneven surfaces

- Vibration damping reducing noise and stress

- Cushioning effect protecting delicate components

- Various densities from soft to rigid

FILM BACKINGS:

- PET films for excellent tensile strength

- Polypropylene for chemical resistance

- Polyimide for high-temperature applications

- Ultra-thin options for discreet bonding

TISSUE & NON-WOVEN:

- Paper tissues for economical solutions

- Non-woven fabrics for tear resistance

- Reinforced composites for heavy-duty applications

- Custom combinations for specific needs

⚡ Advanced Technology Features

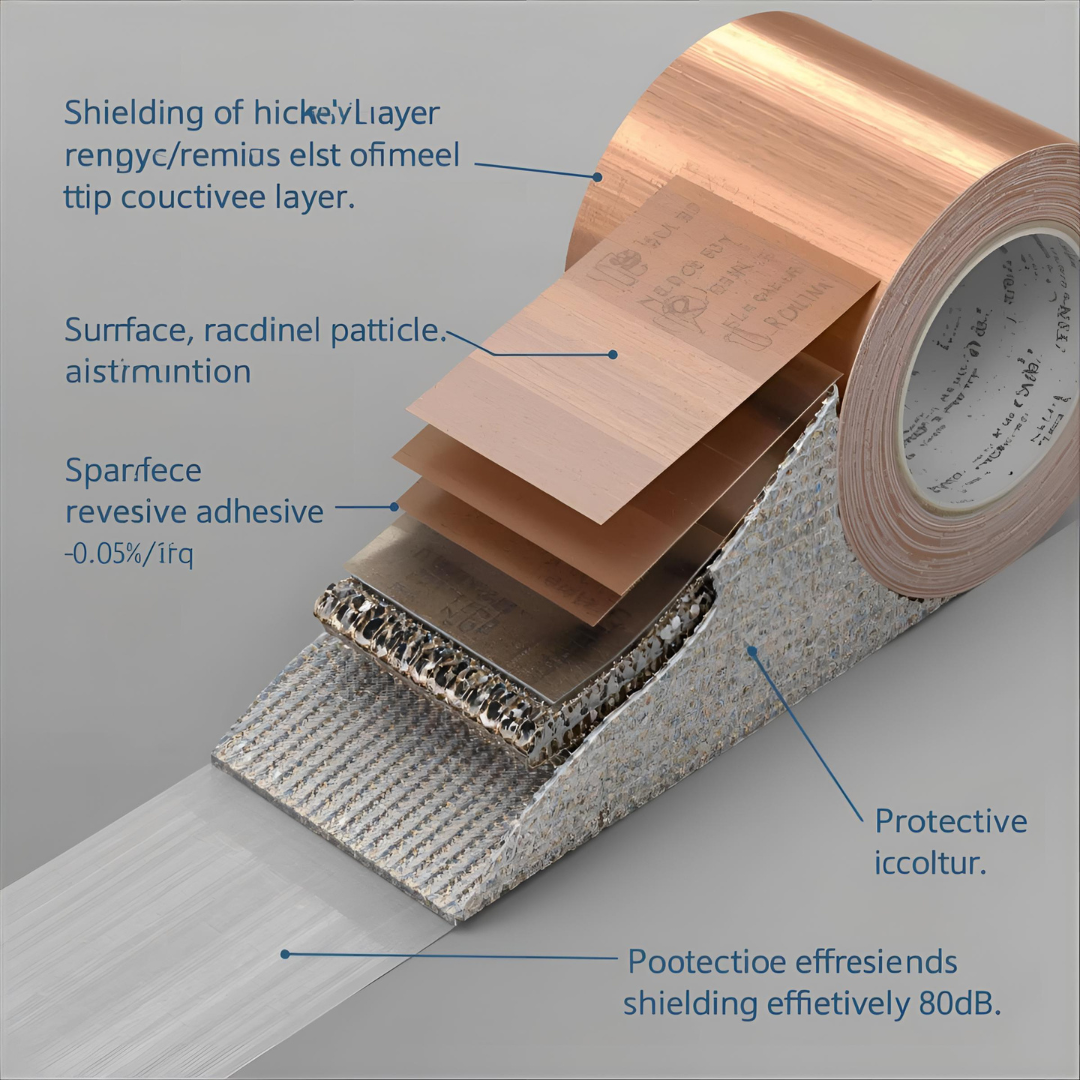

CONDUCTIVE OPTIONS:

- EMI/RFI shielding for electronic applications

- Electrical conductivity for grounding applications

- Thermal management for heat dissipation

- Static dissipation protecting sensitive components

SPECIALTY FORMULATIONS:

- Removable adhesives for temporary bonding

- Repositionable systems allowing adjustment

- High-tack versions for difficult surfaces

- Low-outgassing for optical applications

🚀 Your Technology Selection Partner

Choosing the right double-sided tape technology requires understanding your specific application requirements. Our technical team provides:

➡️ FREE Adhesive Technology Consultation!

- Application analysis and material recommendations

- Performance testing under simulated conditions

- Custom formulation development

- Technical documentation support

Transform your bonding challenges into reliable solutions with the right double-sided tape technology for your specific application requirements.

Contact our adhesive technology experts today!

Keywords Integrated: double-sided tape adhesive technologies, pressure-sensitive adhesive types, backing materials, acrylic-based adhesives, rubber-based systems, foam backings, conductive options, EMI/RFI shielding, removable adhesives, custom formulation development.