The DFM Advantage: Your Secret Weapon Against Delays 🛠️✨

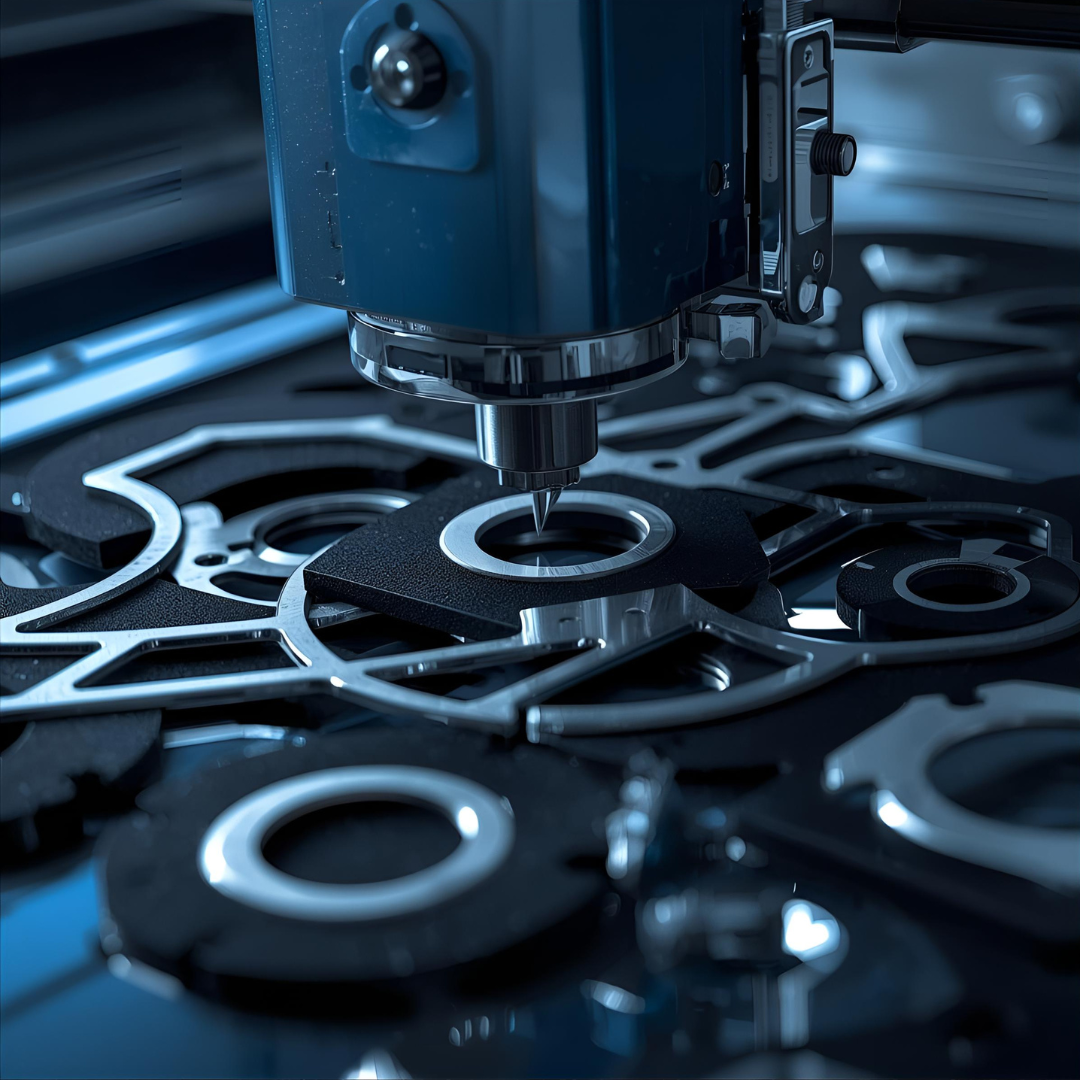

Imagine launching your die-cut project and encountering zero surprises, no redesign cycles, and perfect parts from the first production run. This isn’t fantasy—it’s the power of Design for Manufacturability (DFM) in action. DFM is the proactive engineering approach that transforms potentially problematic projects into smooth, efficient manufacturing successes.

💡 What Exactly is DFM in Die Cutting?

DFM = Early Collaboration × Manufacturing Intelligence

It’s the process of optimizing your design before tooling begins, ensuring your component is engineered for efficient production. Think of DFM as manufacturing foresight—addressing potential issues while they’re still easy and inexpensive to fix on paper.

🚀 The DFM Acceleration Effect: 5 Key Speed Boosters

1. ⏰ ELIMINATE REDESIGN CYCLES

- Problem: 73% of projects require at least one redesign

- DFM Solution: Address manufacturing constraints upfront

- Time Saved: 2-4 weeks per avoided redesign cycle

2. 🛠️ STREAMLINE TOOLING DEVELOPMENT

- Problem: Complex designs require expensive, slow-to-make tooling

- DFM Solution: Simplify geometries for faster tool fabrication

- Time Saved: 1-3 weeks on tooling production

3. 📦 OPTIMIZE MATERIAL USAGE

- Problem: Inefficient nesting wastes material and time

- DFM Solution: Design for optimal material yield

- Time Saved: 15-30% faster production throughput

4. 🔧 SIMPLIFY ASSEMBLY PROCESSES

- Problem: Components that are difficult to handle and place

- DFM Solution: Design for automated assembly

- Time Saved: 40-60% faster installation times

5. ✅ REDUCE QUALITY ISSUES

- Problem: Unexpected defects causing production stops

- DFM Solution: Design out common failure points

- Time Saved: Eliminate 2-5 day quality hold delays

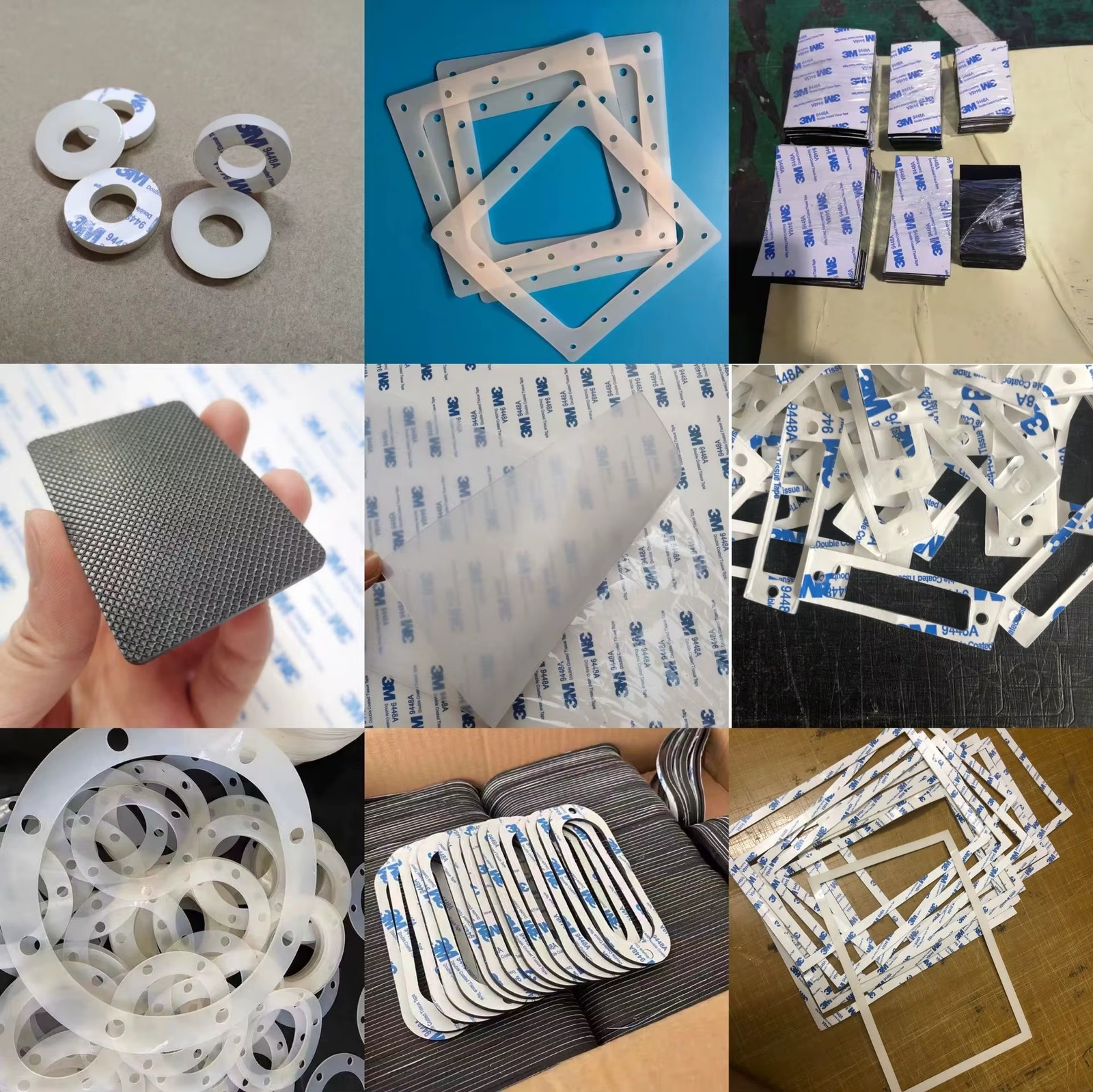

🎯 Real-World DFM Transformations

CASE STUDY: Medical Device Seal

- Initial Design: Complex shape with sharp internal corners

- DFM Revision: Added radii, standardized adhesive thickness

- Results: Tooling cost reduced by 35%, production speed increased by 50%, zero quality rejects

CASE STUDY: Automotive EMI Gasket

- Initial Design: Irregular outline with tight tolerances

- DFM Revision: Relaxed non-critical dimensions, optimized grain direction

- Results: Manufacturing time cut by 60%, material waste reduced by 25%

💡 Your DFM Checklist for Lightning-Fast Projects

DESIGN OPTIMIZATION:

✅ All internal corners have appropriate radii

✅ Tolerances are realistic for application needs

✅ Material selection matches performance requirements

✅ Part orientation considers material grain

MANUFACTURING PREPAREDNESS:

✅ Tooling approach matches volume requirements

✅ Adhesive system suits application method

✅ Liner type supports automated dispensing

✅ Packaging protects parts during shipping

🌟 The DFM Partnership Difference

Successful DFM isn’t about finding problems—it’s about creating solutions through early manufacturer involvement. The best DFM outcomes happen when engineers collaborate with manufacturing experts during the conceptual design phase.

Explore how our DFM process has transformed projects across industries through our case study library.

🚀 Ready to Supercharge Your Next Project?

Stop letting manufacturing surprises derail your timeline. Our DFM experts can help you:

➡️ Get Your FREE DFM Analysis!

- Design review and optimization recommendations

- Material selection guidance

- Cost and timeline projections

- Risk assessment and mitigation strategies

Transform your die-cut project from a timeline gamble to a predictable success. Leverage DFM expertise that turns potential problems into performance advantages.

Contact our engineering team today and experience the DFM difference on your next project!

Keywords Integrated: Design for Manufacturability, DFM strategies, die-cut projects, manufacturing intelligence, tooling development, material optimization, automated assembly, quality improvement, medical device seals, automotive EMI gaskets, design optimization, manufacturing preparedness, DFM partnership, timeline acceleration, cost reduction, production efficiency.