The Manufacturing Metamorphosis: Where Tradition Meets Innovation ✨

The world of precision die cutting is undergoing its most significant transformation in decades. What was once a straightforward conversion process has evolved into a high-tech manufacturing discipline driven by three powerful trends that are reshaping capabilities and possibilities.

🤖 TREND 1: INTELLIGENT AUTOMATION & AI INTEGRATION

The Robotic Revolution:

- AI-powered vision systems achieving 99.95% defect detection

- Automated material handling reducing human intervention by 70%

- Real-time SPC monitoring predicting maintenance needs

- IoT-connected equipment enabling remote factory management

Impact on Quality & Speed:

- Changeover times reduced from hours to minutes

- 24/7 continuous production without quality degradation

- Data-driven optimization of every cutting parameter

- Self-correcting machines maintaining ±0.05mm tolerances

🔬 TREND 2: EXTREME MINIATURIZATION & MICRO-DIE CUTTING

The Shrinking Frontier:

- Medical device components smaller than 1.0mm

- Wearable electronics requiring sub-millimeter features

- Micro-fluidic channels with precision to 0.01mm

- Miniature EMI gaskets for compact electronics

Advanced Technologies Enabling Miniaturization:

- Laser die cutting systems with 20-micron accuracy

- Digital cutting technology eliminating traditional tooling

- High-magnification vision systems ensuring perfection

- Clean room manufacturing for microscopic components

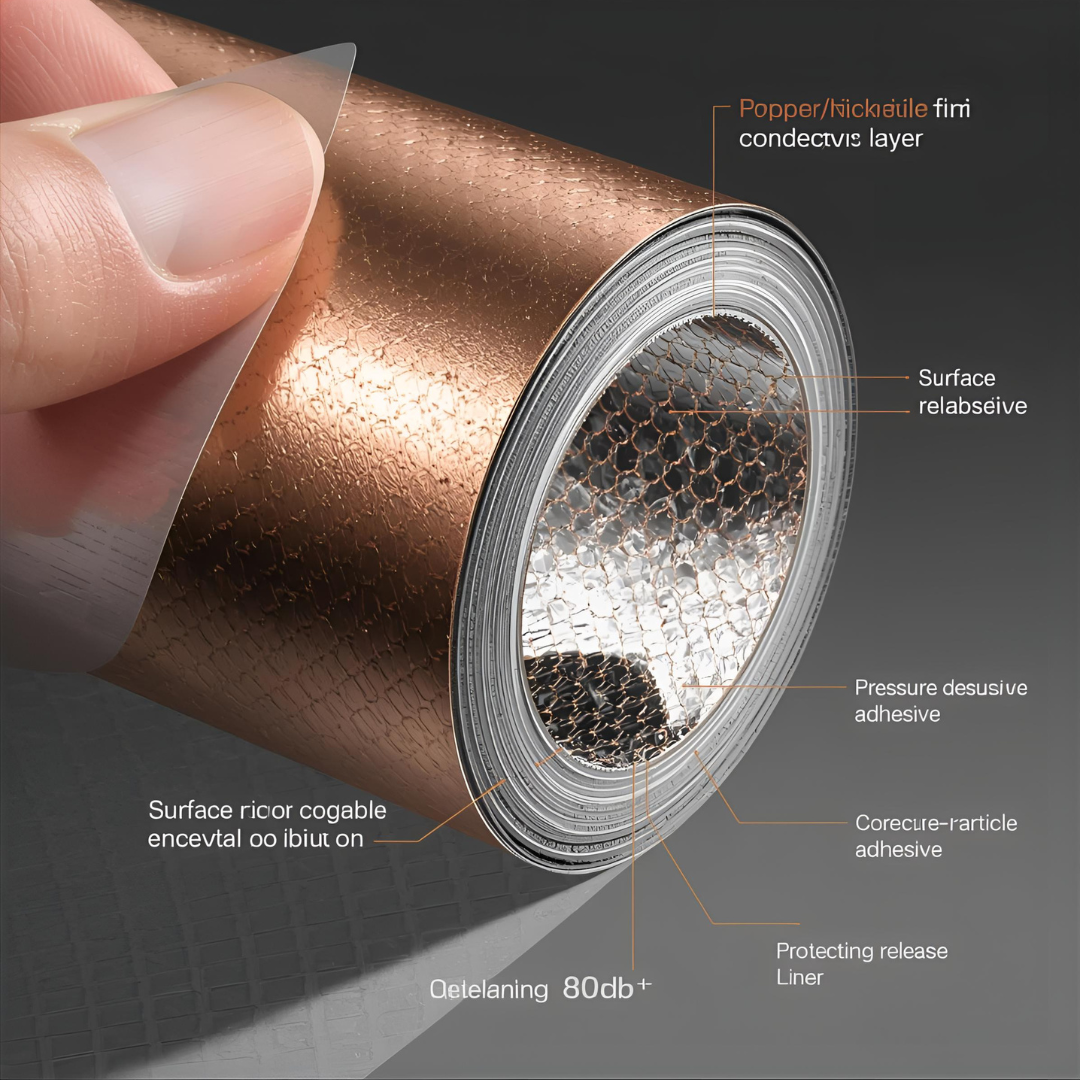

🧠 TREND 3: SMART & FUNCTIONAL MATERIALS

Beyond Basic Substrates:

- Phase-changing thermal materials adapting to temperature fluctuations

- Self-healing polymers extending product lifespan

- Conductive adhesives with customizable resistivity

- Sustainable composites meeting circular economy demands

Intelligent Material Applications:

- Pressure-sensitive films that change color when properly applied

- Thermally conductive but electrically insulating pads

- Memory foams with programmable compression recovery

- Multi-functional laminates combining shielding and cushioning

⚡ The Convergence Effect: When All Three Trends Collide

The most exciting developments occur where these trends intersect:

SMART MEDICAL PATCHES:

- Micro-scale components with bio-sensing materials

- Fully automated production in ISO-7 clean rooms

- Wireless connectivity embedded in flexible substrates

ADVANCED AUTOMOTIVE SENSORS:

- Miniaturized shielding solutions for autonomous vehicles

- Smart adhesive systems indicating proper installation

- AI-optimized production ensuring zero-defect quality

🌍 Global Implications & Industry Impact

SUPPLY CHAIN TRANSFORMATION:

- Localized micro-factories replacing offshore mass production

- Digital inventory systems reducing material waste by 45%

- On-demand manufacturing eliminating minimum order quantities

SUSTAINABILITY ADVANCEMENTS:

- Energy-efficient automation cutting power consumption

- Recyclable smart materials reducing environmental impact

- Precision nesting algorithms maximizing material utilization

🚀 Embracing the Future Today

These trends aren’t coming—they’re here. Forward-thinking manufacturers are already leveraging:

- Machine learning algorithms predicting material behavior

- Advanced material science creating unprecedented capabilities

- Nano-scale precision opening new application possibilities

Explore how these cutting-edge technologies are implemented in our advanced manufacturing facilities.

💡 Your Competitive Advantage Awaits

Staying ahead requires more than just adopting new equipment—it demands a fundamental rethinking of manufacturing strategies and partnerships.

➡️ Schedule Your FREE Future-Readiness Assessment!

Discover how to leverage these trends for:

- 30-50% faster time-to-market

- 20-35% cost reduction through automation

- Access to new markets with advanced capabilities

- Sustainable manufacturing practices

Don’t just watch the revolution—lead it. Transform your manufacturing capabilities with the latest advancements in precision die cutting technology.

Contact our innovation team today to begin your transformation journey!

Keywords Integrated: precision die cutting, AI-powered automation, micro-scale miniaturization, smart responsive materials, laser die cutting, digital cutting technology, phase-changing thermal materials, conductive adhesives, micro-die cutting, automated production, smart manufacturing, miniaturized components, advanced material science, sustainable composites, intelligent automation, micro-electronics, future manufacturing.