The Material Intelligence Behind Perfect Die-Cut Parts 💡

Selecting the right material isn’t just a choice—it’s the foundation of performance in precision die cutting. Understanding these four fundamental material families unlocks optimal solutions for your specific application needs.

📊 Material Property Breakdown: The Essential Guide

🔷 PET FILMS – The Versatile Performer

- Temperature Range: -60°C to +130°C

- Key Strength: Excellent dielectric properties & moisture resistance

- Die-Cutting Edge: Clean cuts with ±0.1mm tolerance achievable

- Prime Applications: Electronic insulation, protective masking, graphic overlays

- Industry Secret: PET with acrylic adhesive offers superior UV resistance

🔥 POLYIMIDE (PI) FILMS – The Extreme Environment Specialist

- Temperature Resilience: -269°C to +400°C continuous

- Key Advantage: Unmatched thermal stability & chemical resistance

- Die-Cutting Challenge: Requires specialized tooling for burr-free edges

- Critical Uses: Flex circuit insulation, motor slot liners, high-temperature masking

- Expert Tip: Golden Kapton films offer superior electrical properties

🧱 INDUSTRIAL FOAMS – The Adaptive Problem-Solver

- Compression Range: 25-75% deflection under load

- Key Benefit: Excellent energy absorption & sealing capability

- Die-Cutting Precision: Kiss-cutting enables easy liner removal

- Primary Applications: Cushioning gaskets, acoustic damping, thermal insulation

- Material Intelligence: Closed-cell foams prevent moisture absorption

🌐 NON-WOVENS – The Economical Workhorse

- Thickness Variety: 0.1mm to 3.0mm standard ranges

- Key Characteristic: Random fiber orientation for uniform strength

- Die-Cutting Efficiency: High-speed processing with minimal tool wear

- Widespread Uses: Filtration media, absorbent pads, surface protection

- Production Insight: Spunbond non-wovens offer superior durability

🎯 Material Selection Matrix: Matching Properties to Applications

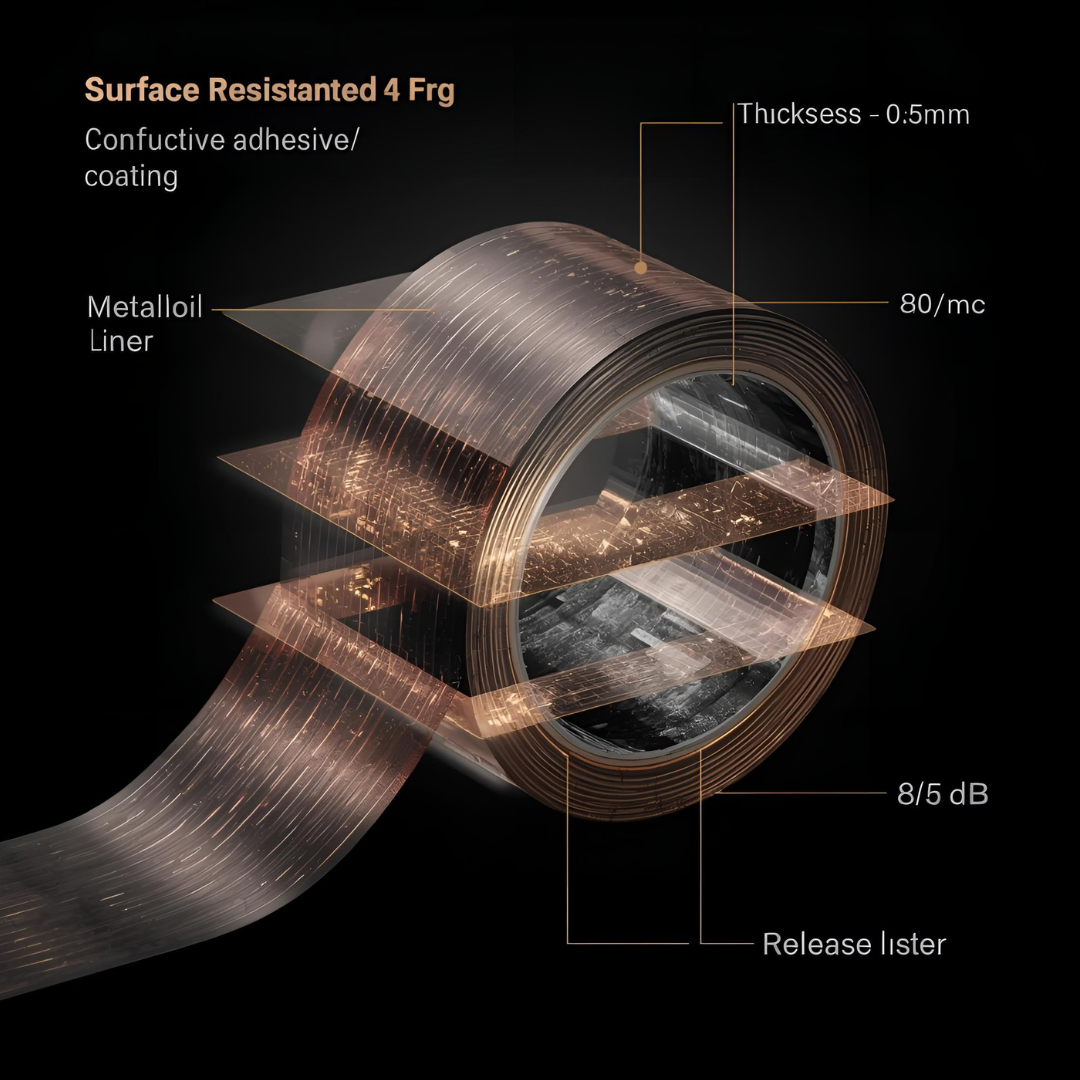

ELECTRONIC SHIELDING: PI films + Conductive adhesives

IMPACT PROTECTION: Cross-linked PE foam + PSA backing

LIQUID FILTRATION: Meltblown non-wovens + Support mesh

THERMAL MANAGEMENT: Graphite-filled films + Silicone adhesive

⚡ Die-Cutting Considerations: Beyond Basic Shapes

MATERIAL-SPECIFIC PROCESSING:

- PET/PI Films: Require sharp tooling for clean edges

- Compressive Foams: Need proper stripping systems

- Fibrous Non-Wovens: Laser cutting reduces particulate

- Adhesive Layers: Liner selection affects conversion efficiency

🚀 Advanced Material Combinations: The Future is Layered

Modern applications demand sophisticated material stacks:

- PET + Foam + Non-woven composites for vibration damping

- PI + Conductive adhesive for EMI shielding

- Multiple foam densities for progressive compression

- Hybrid adhesive systems for challenging substrates

💡 Your Material Success Formula

Choosing materials isn’t about finding the “best” option—it’s about identifying the perfect match for your:

- Environmental conditions

- Performance requirements

- Budget constraints

- Manufacturing process

Explore our comprehensive material library through our product portfolio.

🌟 Ready to Master Your Material Selection?

Don’t let material confusion compromise your project success. Our material scientists specialize in matching the perfect substrate to your specific application requirements.

➡️ Get FREE Material Selection Guidance & Samples!

Receive expert recommendations plus:

- Material comparison chart

- Application-specific suggestions

- Sample kit for testing

- DFM analysis report

Transform your material challenges into performance advantages with expert guidance and precision conversion capabilities.

Connect with our material experts today for personalized solutions!

Keywords Integrated: PET film properties, PI thermal resistance, foam compression, non-woven characteristics, precision die cutting, electronic insulation, thermal stability, Kapton films, energy absorption, kiss-cutting, filtration media, conductive adhesives, EMI shielding, material selection, DFM analysis, precision conversion, industrial foams, protective masking, acoustic damping.