The Ultimate Guide to EMI Shielding, ESD Protection, and Advanced Applications

1. What Are Conductive Tapes?

Conductive tapes are specialized adhesive tapes engineered with metal particles (e.g., copper, nickel, silver) or conductive polymers to provide electrical conductivity, electromagnetic interference (EMI) shielding, and electrostatic discharge (ESD) protection. They serve as critical components in modern electronics, automotive systems, and medical devices by creating reliable electrical pathways while maintaining strong adhesion.

2. Types of Conductive Tapes

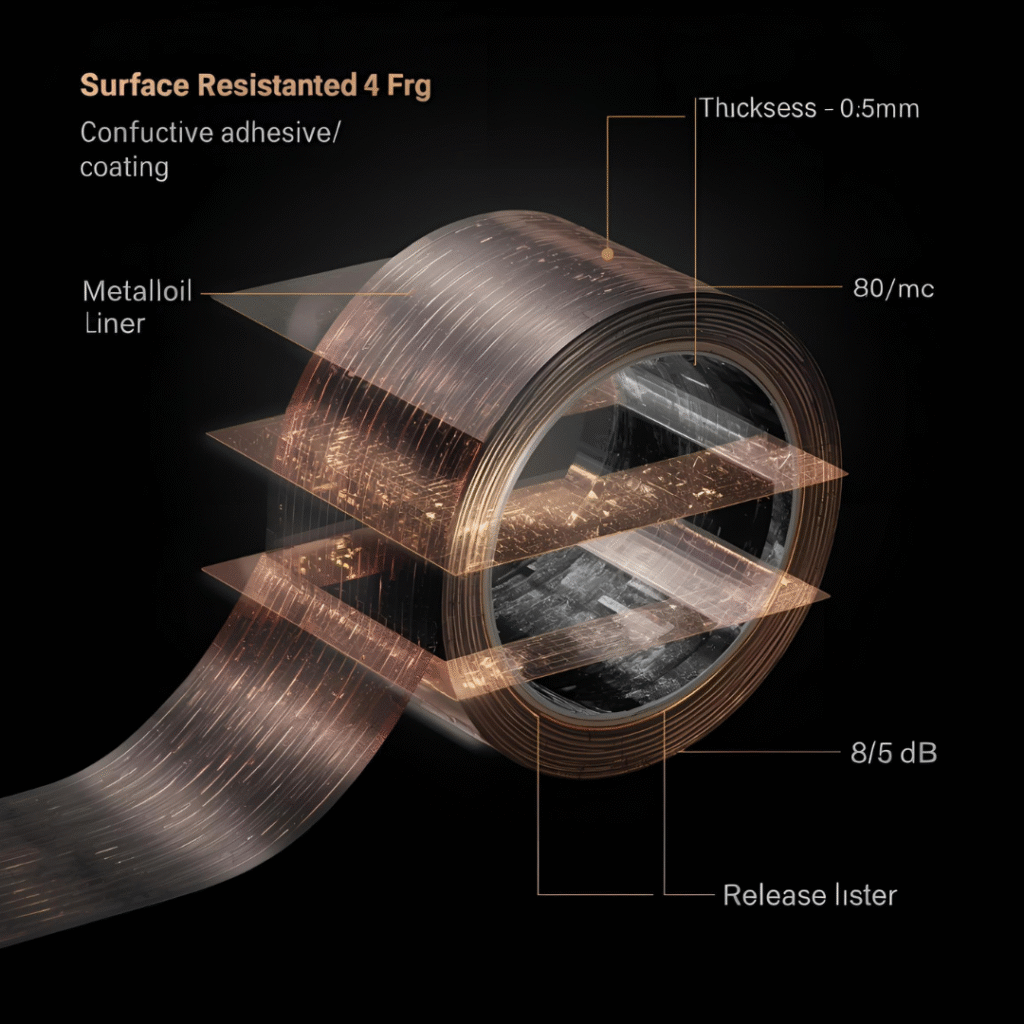

- Metal Foil Tapes (Copper/Aluminum)

- Properties: Low surface resistance (<0.05 Ω/sq), high shielding effectiveness (60–100 dB), thickness: 0.03–0.1mm.

- Applications: PCB shielding, cable wrapping, grounding.

- Conductive Fabric Tapes (Nickel/Copper-Coated Polyester)

- Properties: Flexible, bend-resistant (0.1–0.5 Ω/sq), ideal for irregular surfaces.

- Applications: Wearable devices, flexible circuits, gap shielding.

- Conductive Foam Tapes (Metal-Coated Polyurethane)

- Properties: High compressibility (>70% recovery), vibration damping, thickness: 0.5–2.0mm.

- Applications: Enclosure shielding, door seals, anti-vibration grounding.

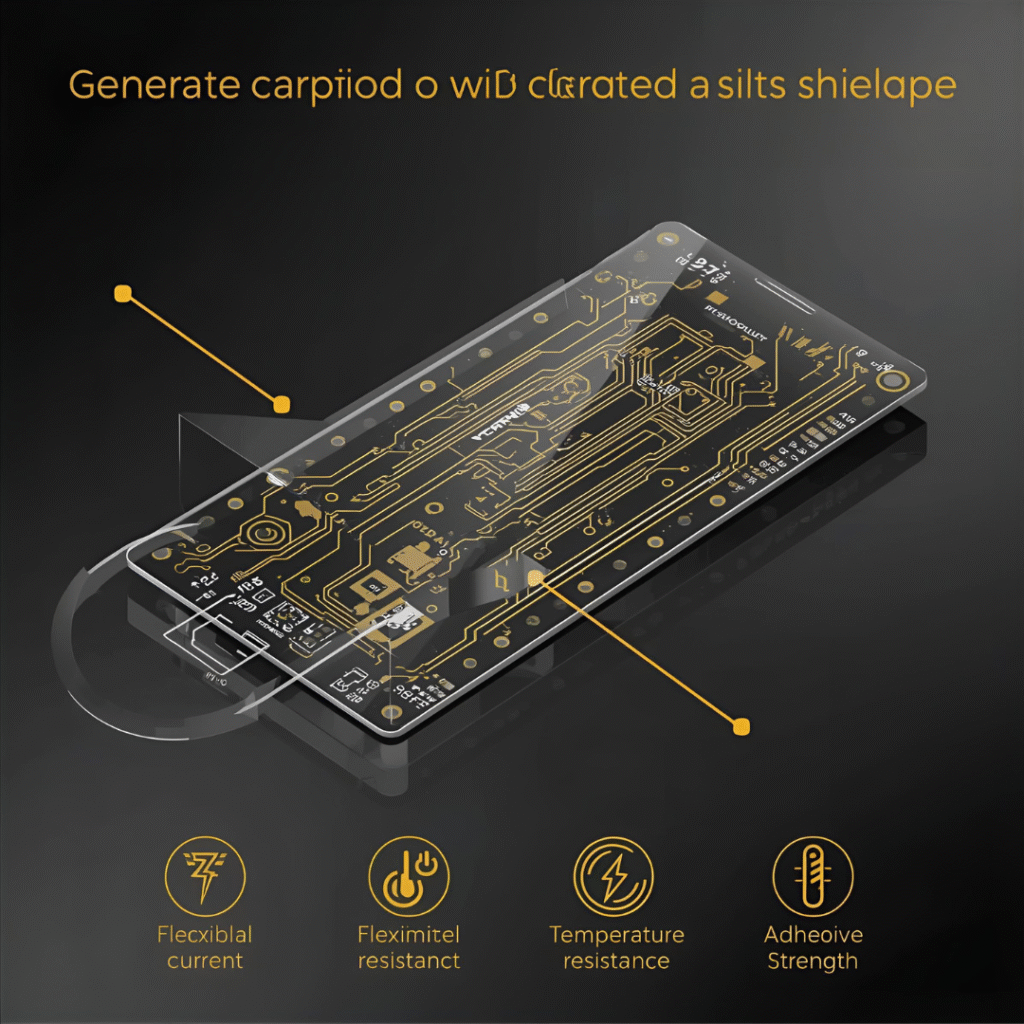

- Anisotropic Conductive Films (ACF)

- Properties: Z-axis conductivity, XY insulation, precise bonding.

- Applications: Display connections, chip-on-flex (COF) bonding.

3. Key Performance Metrics

| Parameter | Typical Range | Importance |

|---|---|---|

| Surface Resistance | 0.01–10 Ω/sq | Determines conductivity efficiency |

| Shielding Effectiveness | 60–100 dB (at 1 GHz) | Critical for EMI/RFI suppression |

| Peel Strength | 5–30 N/25mm | Ensures bonding reliability |

| Temperature Resistance | -40°C to 150°C | For automotive/industrial use |

| Thickness | 0.03–2.0 mm | Fits compact spaces |

4. Industry Applications

- Electronics: Smartphone EMI shielding, 5G base station modules.

- Automotive: EV battery management systems (BMS), radar shielding.

- Medical: ESD-safe equipment, ISO 10993-compliant devices.

- Aerospace: Avionics shielding, satellite communication systems.

5. Selection Guidelines

- High-Frequency Shielding: Copper foil tapes (>80 dB at 10 GHz).

- Flexible Surfaces: Conductive fabric tapes (耐弯折 >100,000 cycles).

- Vibration-Prone Environments: Conductive foam tapes (压缩回弹 >70%).

- Precision Bonding: ACF tapes for fine-pitch connections.

6. Future Trends & Challenges

- Trends: Nanomaterial integration (e.g., graphene), hybrid tapes with thermal conductivity, eco-friendly formulations (halogen-free).

- Challenges: Shielding effectiveness above 100 dB for 6G, thickness below 0.05mm for ultra-thin devices.

7. Why Choose Professional Conductive Tapes?

Technical support for adhesion and conductivity testing.

Custom die-cutting for complex shapes.

Compliance with UL, RoHS, and REACH standards.

Products by Category

-

Carbon Fiber Heating Tape – Double-Sided Conductive Adhesive for Flexible Heaters

-

Custom 3M VHB Die Cut Adhesive

Original price was: $0.20.$0.10Current price is: $0.10. -

Custom High-Strength Thermal Tape – Glass Fiber Double-Sided Adhesive for LED Heat Dissipation

-

High-Performance Thermal Conductive Tape – For LED Heat Sinks & Electronics Cooling

-

Sublimation Heat Transfer Tape – Blue Die-Cut Thermal Tape for Heat Press Applications