ouble-Sided Tapes

1. What Are Double-Sided Tapes?

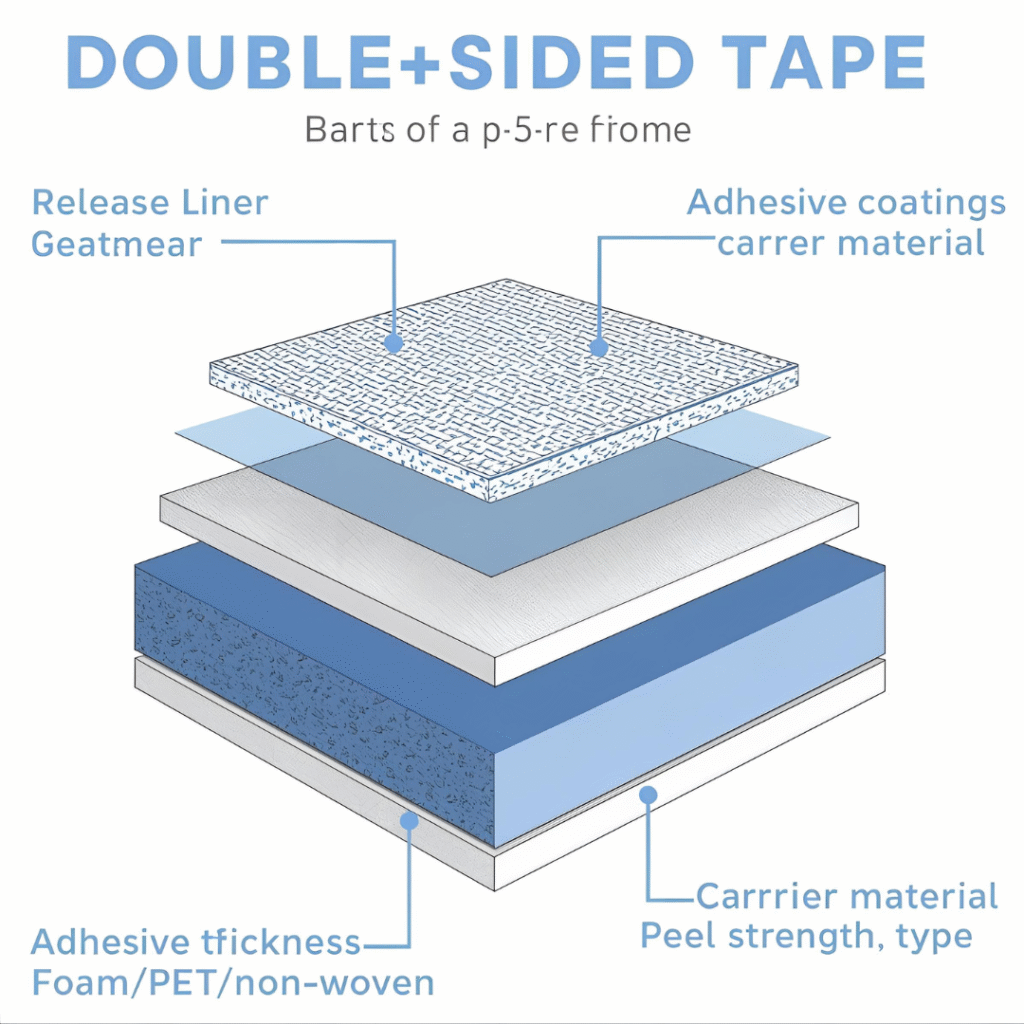

Double-sided tapes are pressure-sensitive adhesive (PSA) materials coated with adhesive on both sides, designed for bonding two surfaces together without visible fasteners. They provide clean, efficient, and permanent bonding solutions across industries ranging from electronics to construction.

2. Key Types of Double-Sided Tapes

- Foam Tapes (e.g., VHB Tapes):

- Properties: High thickness (0.5mm–3mm), shock absorption, conformability.

- Applications: Mounting mirrors, automotive trim, panel bonding.

- PET/Polyester Tapes:

- Properties: Thin (0.05mm–0.2mm), high tensile strength, temperature resistance.

- Applications: PCB mounting, display assembly, graphic installation.

- Non-Woven Tapes:

- Properties: Soft, flexible, ideal for irregular surfaces.

- Applications: Carpets, flooring, upholstery.

- Acrylic vs. Rubber Adhesives:

- Acrylic: Weather/UV resistant, long-term durability (automotive/outdoor use).

- Rubber: Initial tack, flexibility (indoor/short-term applications).

3. Critical Performance Parameters

- Adhesion Strength:

- Peel Strength: 10–50 N/25mm (varies by substrate).

- Shear Strength: 50–200 hours (at specified load/temperature).

- Temperature Resistance:

- Standard Tapes: -20°C to 80°C.

- High-Temp Tapes: -40°C to 150°C (acrylic-based).

- Thickness & Conformability:

- Thin Tapes (0.05mm): Smooth surfaces (glass/metal).

- Thick Tapes (1–3mm): Irregular surfaces (textured walls/rivets).

- Environmental Resistance:

- UV/Water Resistance: Critical for outdoor applications.

- Chemical Resistance: Resists solvents/oils (industrial environments).

4. Industry-Specific Applications

- Electronics:

- Mounting components, shielding EMI, securing displays.

- Example: Thin PET tapes for smartphone assembly.

- Automotive:

- Emblem attachment, trim mounting, panel bonding.

- Example: VHB tapes for rearview mirror installation.

- Construction:

- Flooring installation, panel bonding, signage mounting.

- Example: Non-woven tapes for carpet seams.

- Medical:

- Securing devices, wearable sensors, wound care products.

- Example: Skin-friendly tapes for ECG electrodes.

5. How to Choose the Right Double-Sided Tape?

| Factor | Consideration |

|---|---|

| Substrate | Smooth vs. rough surfaces; low/high surface energy materials. |

| Environment | Indoor/outdoor use; exposure to UV, moisture, or chemicals. |

| Thickness | Gap-filling needs; irregular surface compensation. |

| Duration | Permanent vs. temporary bonding; removable options. |

| Certifications | UL, RoHS, REACH compliance for specific industries. |

6. Customization & Support

Testing Services: Peel/shear adhesion tests, environmental aging reports.

Die-Cutting: Precision shapes for automated application.

Adhesive Variants: Acrylic, silicone, or rubber-based options.

Liner Types: Paper, PET, or polypropylene liners for easy handling.