Mylar Films/Electrical Insulation Materials:

1. Material Overview: What Are Mylar Films?

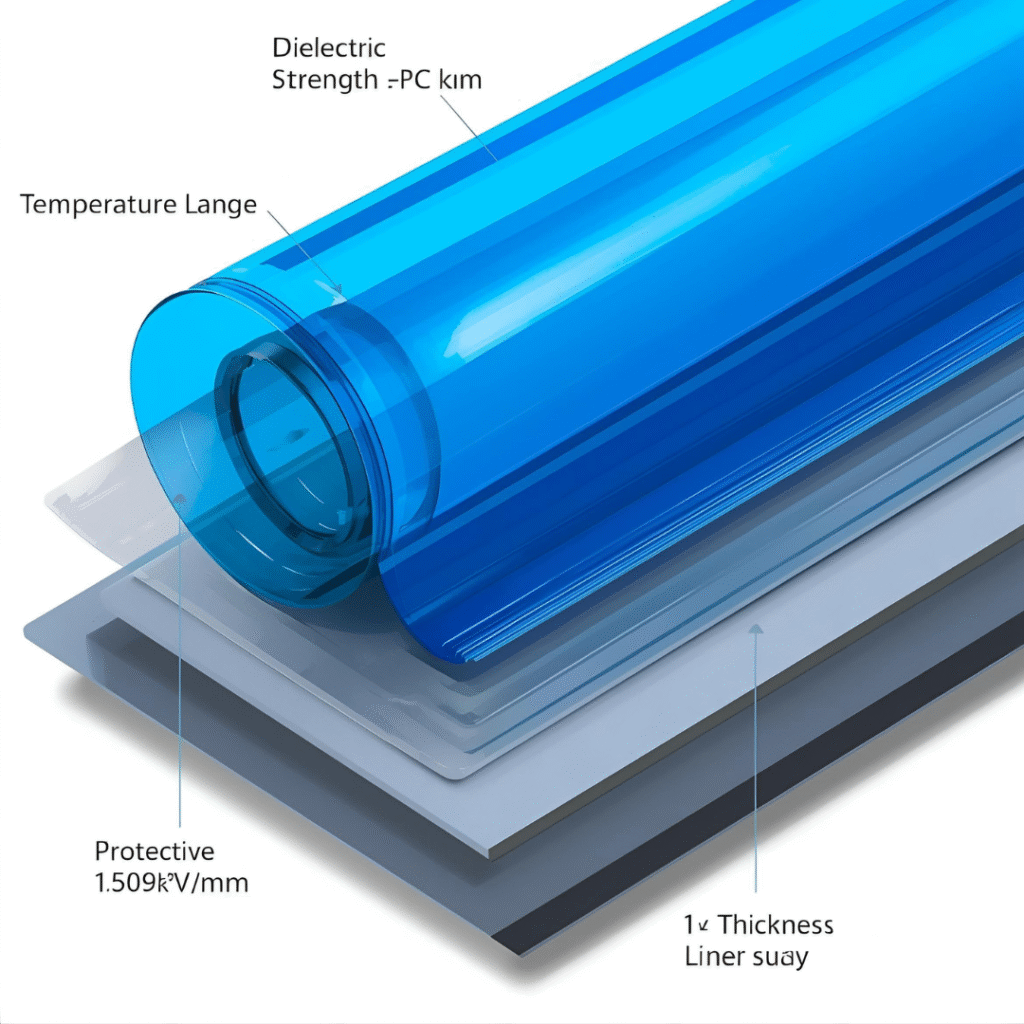

Mylar films (polyester films) are high-performance electrical insulation materials widely used in electronics, electrical systems, and industrial applications due to their exceptional dielectric strength, mechanical properties, and temperature stability. Key variants include:

- PET Mylar Films (Polyethylene Terephthalate): Cost-effective general-purpose insulation.

- PI Mylar Films (Polyimide, e.g., Kapton®): High-temperature resistance up to 250°C for extreme environments.

- Composite Mylar Films: Reinforced with fibers or foils (e.g., DuPont™ Nomex®) for enhanced mechanical strength.

2. Key Performance Parameters (Why Choose Mylar Films?)

- Electrical Properties

- Dielectric Strength: ≥150 kV/mm (up to 300 kV/mm for PI films).

- Surface Resistance: 10¹⁴–10¹⁶ Ω (prevents leakage and arcing).

- Dielectric Constant: 3.0–3.5 (at 1 kHz).

- Mechanical & Physical Properties

- Tensile Strength: 150–250 MPa (up to 400 MPa for PI films).

- Temperature Range: -269°C to +250°C (PI films).

- Thickness Range: 0.025mm–0.5mm (suitable for precision die-cutting).

- Environmental Resistance

- Chemical Resistance: Withstands oils, solvents, and acids (PI films excel).

- Flame Retardancy: UL 94 V-0 rated (most PI and composite films).

- Humidity Stability: Water absorption <0.8% (0.2% for PI films).

3. Selection Guide: How to Choose the Right Insulation Film?

| Application Scenario | Recommended Material | Key Advantages |

|---|---|---|

| Motor Slot Insulation | PET Mylar Films | Cost-effective, high dielectric strength |

| Flexible Printed Circuits (FPC) | PI Mylar Films | Solder-temperature resistance, dimensional stability |

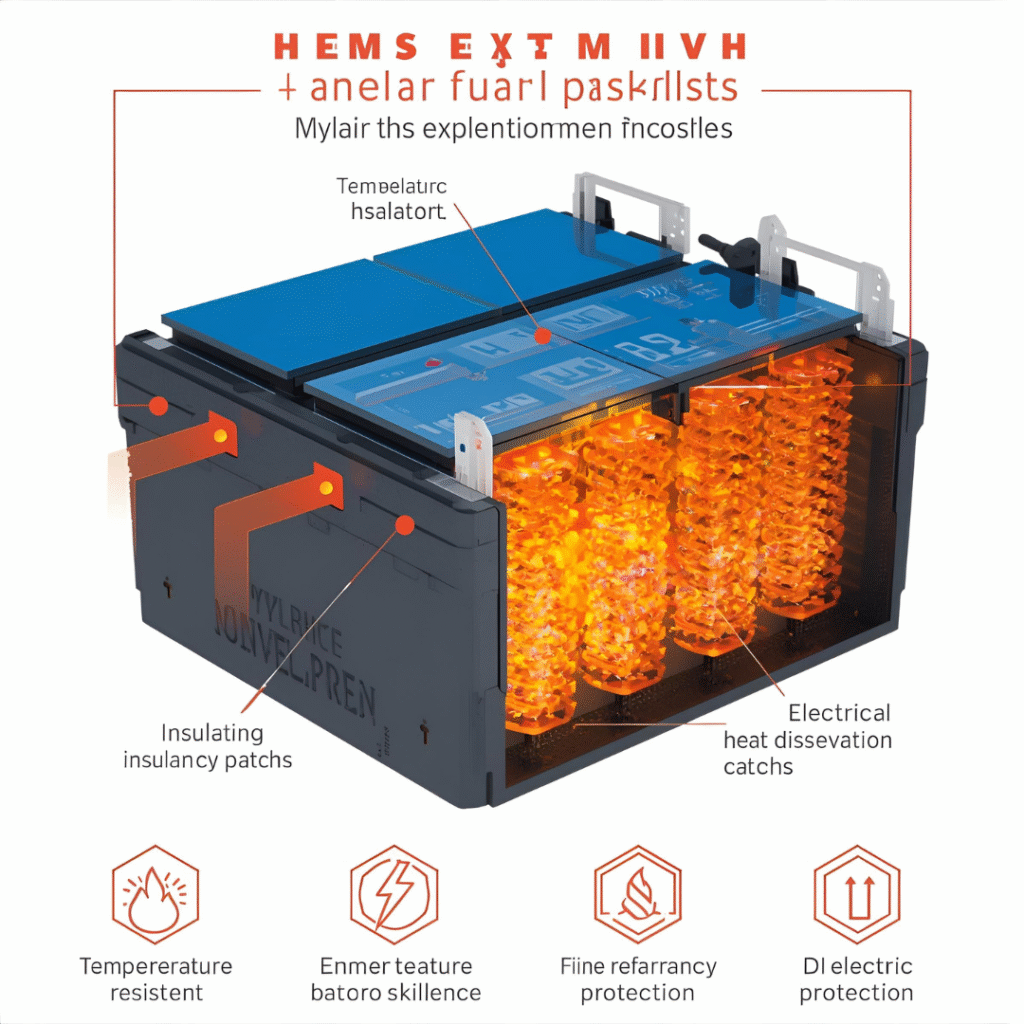

| EV Battery Insulation | Nomex® Composite Films | Flame retardant, high-temperature resistant, mechanically robust |

| Transformer Layer Isolation | Polyimide Films | Corona resistance, long lifespan |

4. High-End Application Cases

- Aerospace

PI films are used in satellite cable insulation, enduring extreme temperature fluctuations and radiation. - Medical Devices

ISO 10993-compliant medical-grade Mylar films for MRI equipment insulation and surgical instrument packaging. - New Energy Sector

PET-based insulation for photovoltaic backsheets and PI/Nomex® films for EV battery module isolation.

5. Customization and Processing Services

We offer:

Certification Support: Full compliance with UL, RoHS, REACH, and ISO 9001 standards.

Precision Die-Cutting: ±0.1mm tolerance for complex shapes (e.g., perforated, multi-edge designs).

Composite Processing: Lamination with copper foil, conductive adhesive, or non-woven fabrics for multifunctional integration.

3M 467 Double-Sided Adhesive

- Strong Bonding Power: Features industrial-grade 3M adhesive for secure attachment to metal, plastic, glass, and more.

- Ultra-Thin Profile: Only 0.05mm thick, providing seamless application—ideal for electronics, nameplates, and labels.

- Heat and Weather Resistant: Maintains reliable adhesion even in high-temperature and humid environments.

- Easy to Use: Simple to peel and cut, suitable for both manual and automated production processes.