“Your prototype die-cut parts will cost $X.” ✨

If that number makes your heart race (and not in a good way), you’re not alone. Many engineers face sticker shock with low-volume die-cutting. But here’s the secret: traditional high-volume pricing models don’t apply to small batches.

The good news? With smart strategies, you can dramatically reduce costs while maintaining the precision your project demands.

💰 Understanding the Cost Drivers: Where Does Your Money Go?

Before solving cost, let’s understand what you’re paying for:

- Tooling/Tooling Setup (40-60%) – The largest chunk for small runs

- Material Waste (15-25%) – Especially significant with expensive specialty materials

- Labor & Machine Time (20-30%) – Setup, running, and quality control

- Secondary Operations (10-20%) – Lamination, packaging, etc.

Now, let’s tackle these systematically.

🎯 7 Cost-Saving Strategies for Smart Engineers

1. 🛠️ CHOOSE THE RIGHT TOOLING TECHNOLOGY

Stop assuming steel rule dies are your only option!

- Kiss-Cutting: Uses standard tooling – often most economical

- Laser Die-Cutting: No tooling costs for prototypes

- Digital Cutting: Perfect for R&D samples

- Sample Kits: Use existing dies from manufacturer’s library

2. 📐 OPTIMIZE YOUR DESIGN FOR MANUFACTURING

Small tweaks = big savings:

- Increase corner radii from 0.5mm to 1.0mm

- Standardize adhesive thickness when possible

- Avoid ultra-tight tolerances (±0.2mm vs ±0.1mm)

- Design for efficient material nesting

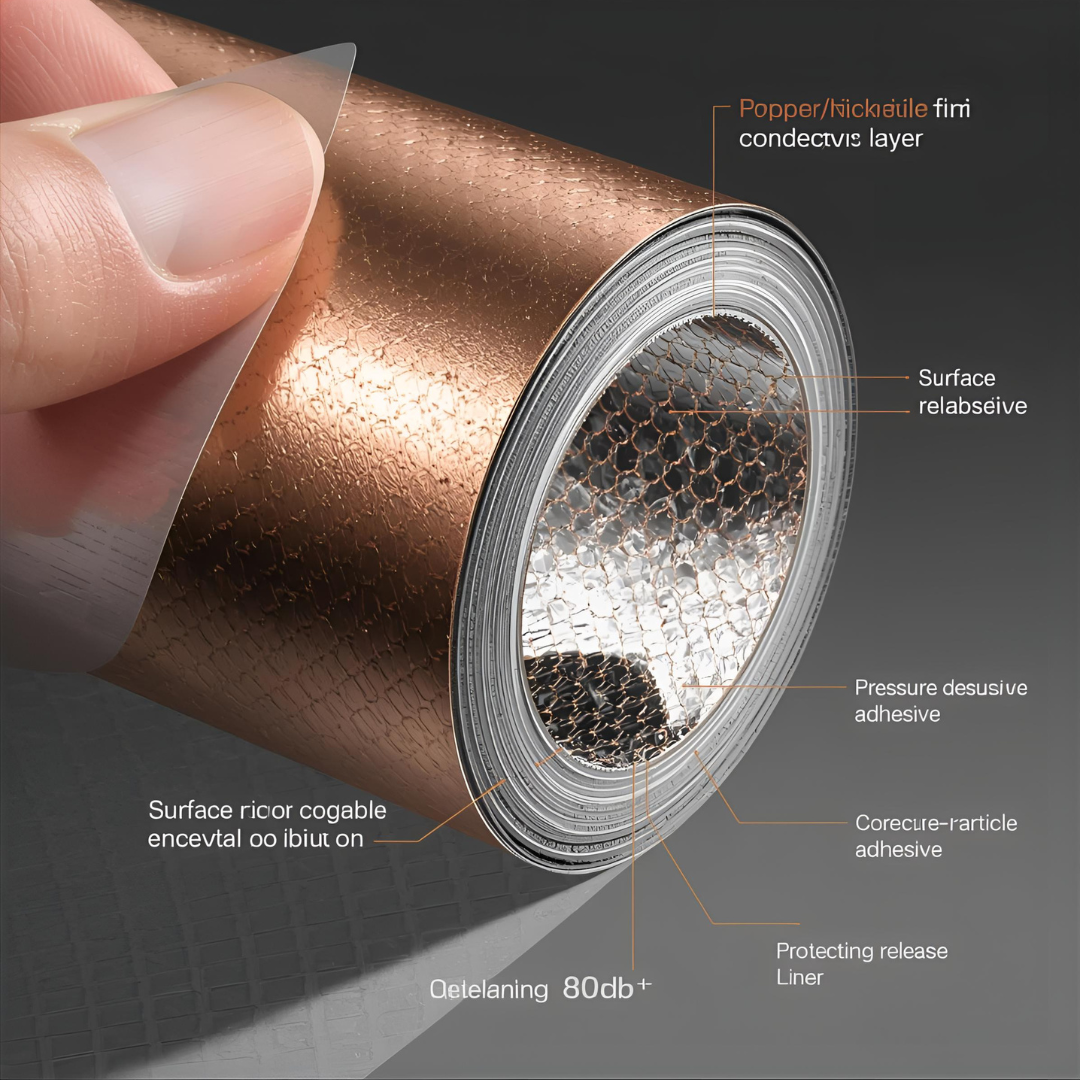

3. 📦 SMART MATERIAL SELECTION

Material costs can make or break your budget:

- Consider functional alternatives (PET vs. PI where suitable)

- Use manufacturer’s stock materials when possible

- Order sample kits to test multiple options

- Avoid over-specifying material performance

4. 🔄 BATCH YOUR PROTOTYPING

Instead of multiple small orders:

- Combine related projects into single production runs

- Order extra samples for future testing

- Plan your iterations to minimize setup changes

5. 🏭 PARTNER, DON’T JUST PURCHASE

The right manufacturer relationship matters:

- Find low-volume specialists (like us!)

- Leverage their material inventory

- Use their engineering expertise early in design

- Build a relationship for better pricing

6. ♻️ MINIMIZE SECONDARY OPERATIONS

Every extra step costs money:

- Accept standard packaging when possible

- Combine operations where feasible

- Simplify quality requirements for prototypes

7. 📊 THINK BEYOND UNIT PRICE

Sometimes paying more upfront saves overall:

- Better materials might reduce assembly costs

- Higher precision can eliminate downstream issues

- Professional conversion saves engineering time

💡 Real-World Example: 63% Cost Reduction

A client needed 50 medical device prototypes with complex shapes in expensive silicone adhesive. Initial quote: $1,850.

After implementing our recommendations:

- Switched to laser cutting (eliminated $650 tooling)

- Used alternative medical-grade acrylic adhesive (saved $300)

- Optimized design for better material yield (saved $175)

- Combined with another project (saved $150 setup)

Final cost: $675 – with identical functional performance.

🚀 Your Path to Affordable Precision

Small-volume die-cutting doesn’t have to break your budget. The key is partnering with a manufacturer who understands low-volume economics and offers flexible solutions.

Ready to get quality die-cut parts without the shocking price tag?

Explore our low-volume solutions: [Low-Volume Die-Cutting – https://diecutchina.com/offerings/]

➡️ Send your design for a FREE cost-reduction analysis. Our engineers will identify specific ways to reduce your project costs while maintaining quality.

📧 Get Your Free Cost Reduction Analysis!

Quality parts shouldn’t cost a fortune.

[Contact Us Today – https://diecutchina.com/contact/]

Keywords Integrated: low-volume die-cutting costs, prototype die-cut parts, small batch production, cost-effective die-cutting, kiss-cutting, laser die-cutting, R&D samples, low-volume specialists, medical device prototypes, silicone adhesive, medical-grade acrylic adhesive, low-volume economics, cost-reduction analysis, affordable precision parts.